-

Carbon Fiber Steering Wheel Testing, Validation, and Manufacturing

The 2023 Steering wheel design was a collaborative project between Materials and Manufacturing, Controls, and Electrical, with key members Jonas (MnMs), Indigo (Controls), and Jaydon (Electrical). I oversaw the design development of the carbon wheel enclosure and interface with the electrical faceplate while managing carbon layup testing and process development to optimize our layup, working…

-

Monocoque Steering Column and Mount

With the 2023 Monocoque, our previous method of welding some tubes onto the frame as a steering column mount wasn’t going to work. After numerous prototype mounts had been produced and failed well before target loads, I was assigned this project by my team captain. We needed a solution that we could manufacture relatively quickly…

-

Carbon Fiber Suspension Link Development

This year, we decided to try designing and manufacturing our own in-house carbon fiber suspension links as opposed to welded 4130 steel links. Carbon links have the potential to be stiffer and lighter, and also help reduce unsprung mass in our vehicle. They can also have a larger second moment of area relative to low-diameter…

-

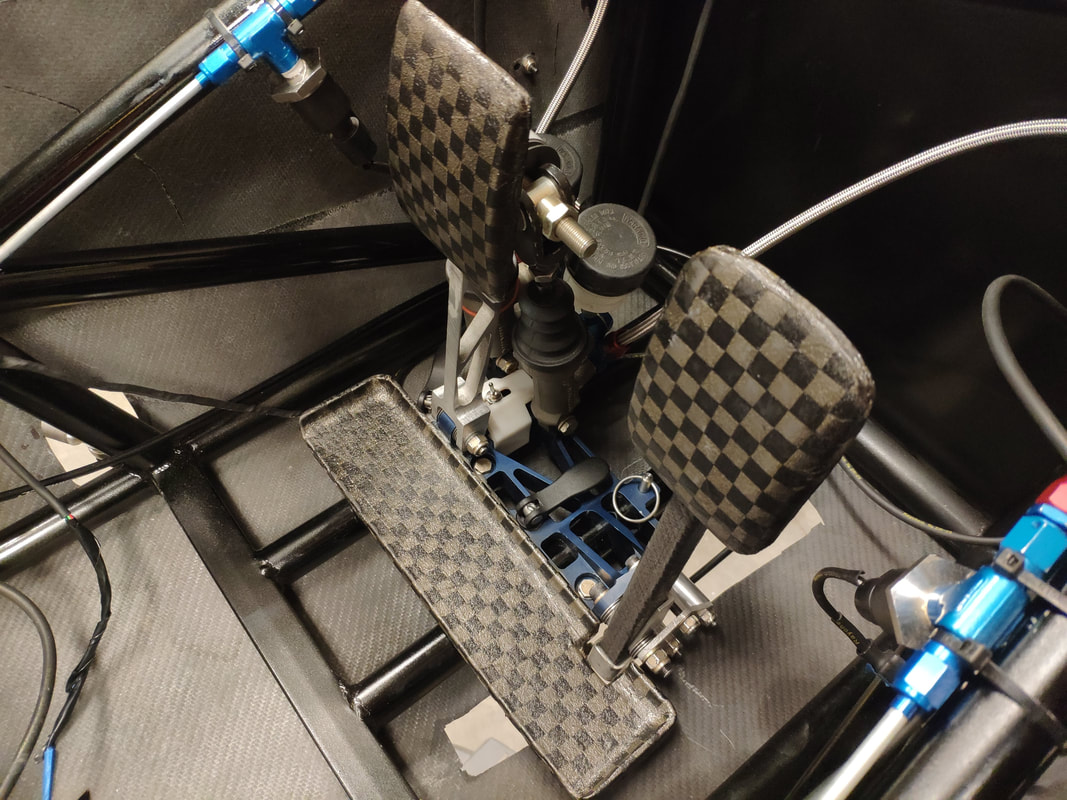

Drive-By-Wire Pedalbox R&D

Anticipating ownership of the pedalbox project for the 2022-23 season, I’ve set a goal for us to not only have fully electronic throttle control, but also a lighter, simpler, compression molded carbon fiber pedalbox design. Most of my work so far has been on developing a good system for sensing throttle pedal position, and you…

-

Brake Pedal Design Overhaul

Over the course of my first few months on the team, I was tasked with redesigning the brake pedal. My foci were ease of manufacturability, increased torsional stiffness (the previous pedal was unacceptably poor in this respect), and minimal weight gain while maintaining the same mounting geometry. The pedal has to withstand a 2000N force…

-

Custom Molded Carbon Fiber Seat Prototyping

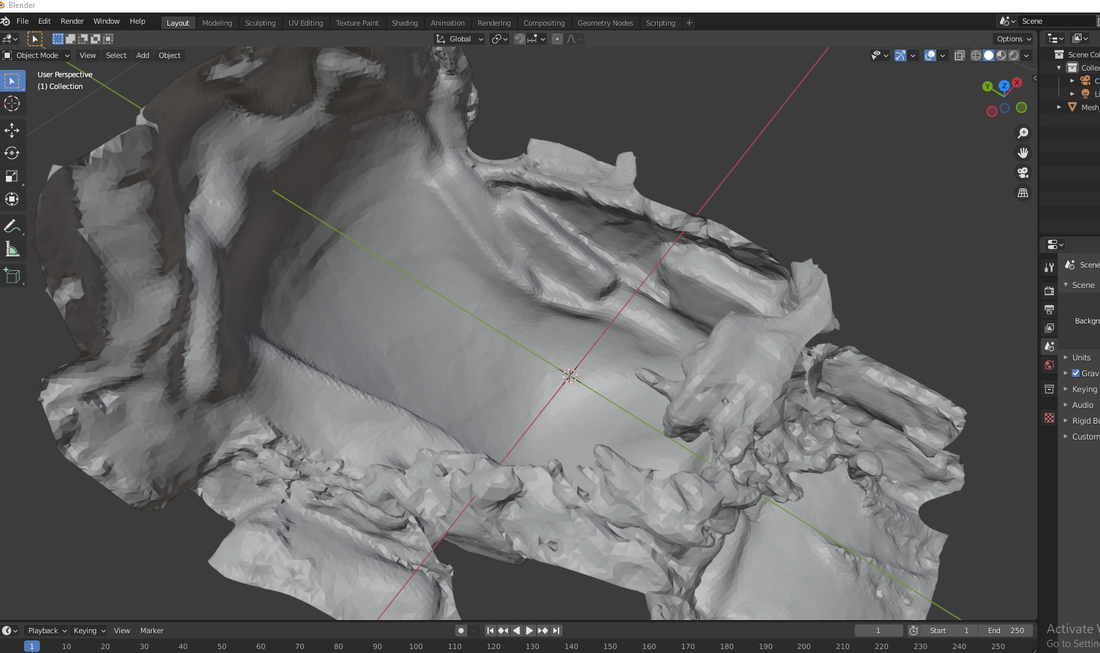

When I was tasked with coming up with a way to make this year’s seat, I had the inspiration to use beads and resin to make a custom mold around our main driver’s body, and then use an iPhone with LIDAR to scan the 3D geometry of the mold impression so that we could easily…

-

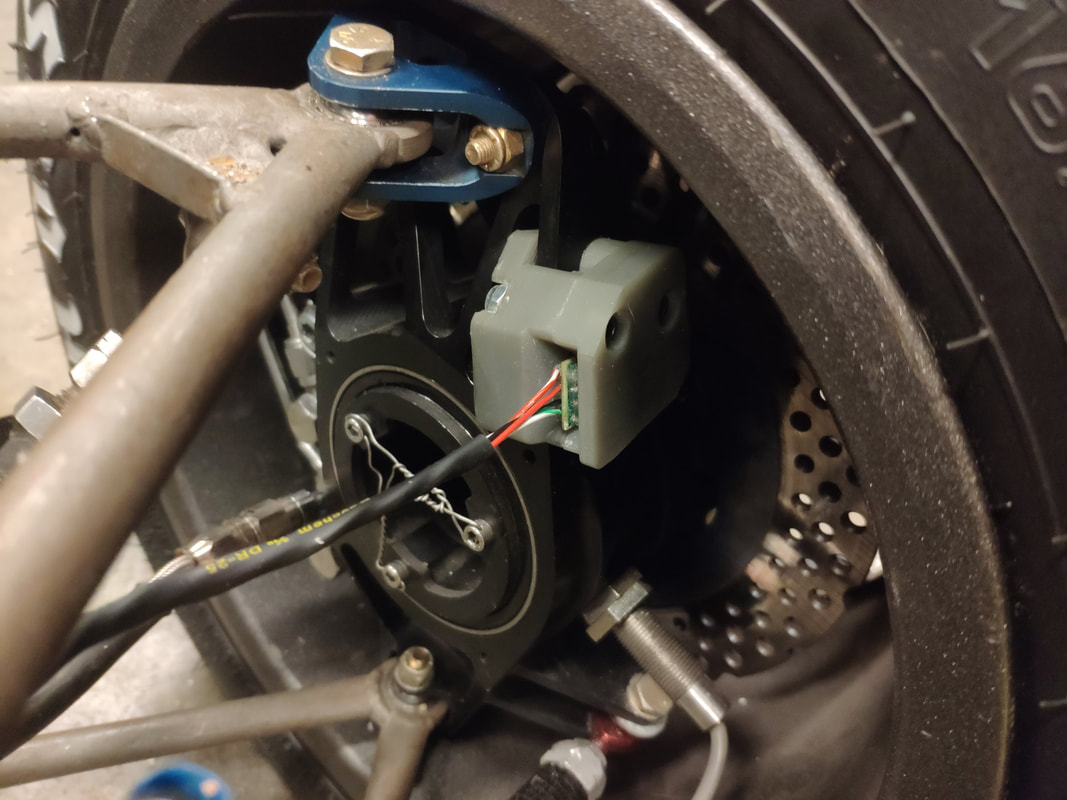

Brake Overtravel Detection

One of FSAE’s requirements is that a switch be placed behind the brake pedal such that if brake pressure is lost and the pedal overtravels its normal range, engine power is cut. I stepped in to design a housing that would allow us to fine-tune the position of this switch and allow simple mounting or…

-

Brake Temperature Sensor Housing Design

This is a design-in-a-day where I wanted to develop a system to mount our brake temperature sensors on our existing uprights securely and protect them from the harsh environment (read: rain, debris). Below you can check out my Solidworks design and front upright sensor positioning assembly, resin printed housings, brake temp sensors with deutsch connectors…

-

Carbon Fiber Heel Plate and Pedal Faces

This is a quick project where I machined Rohacell foam using a manual mill and belt sander to create forms and laid up prepreg spread-tow carbon around the Rohacell forms before vacuum bagging and oven-curing, then epoxying on: Skills and Learning ••••◦ Composites Layup and Vacuum Bagging •••◦◦ Machining