The 2023 Steering wheel design was a collaborative project between Materials and Manufacturing, Controls, and Electrical, with key members Jonas (MnMs), Indigo (Controls), and Jaydon (Electrical). I oversaw the design development of the carbon wheel enclosure and interface with the electrical faceplate while managing carbon layup testing and process development to optimize our layup, working closely with Jonas and Indigo and guiding our layup procedures.

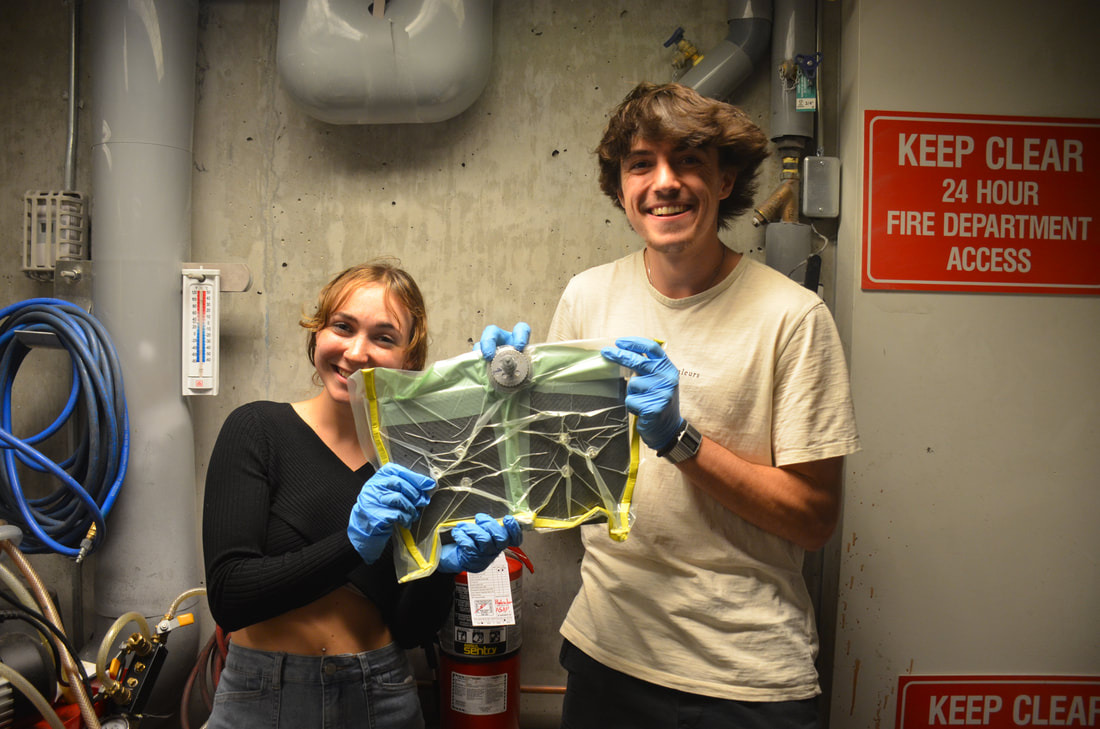

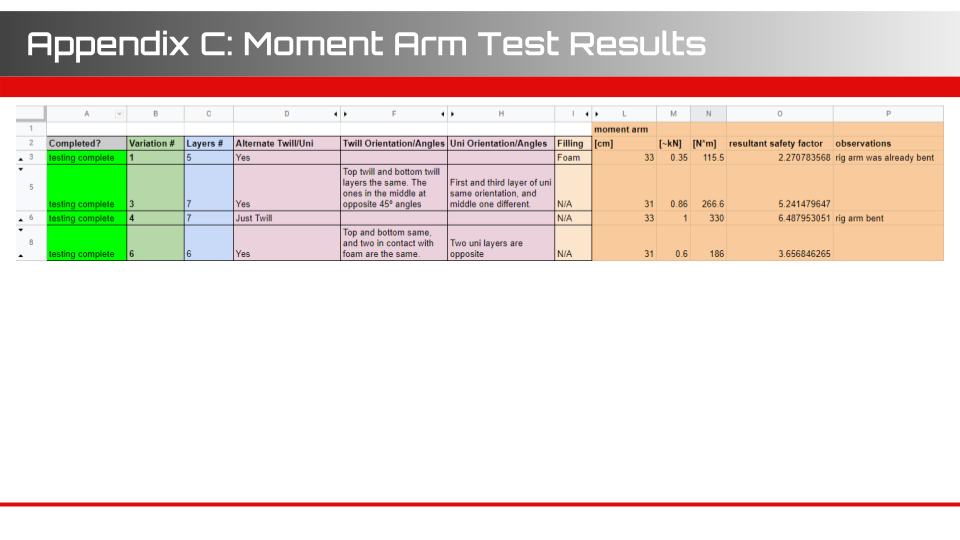

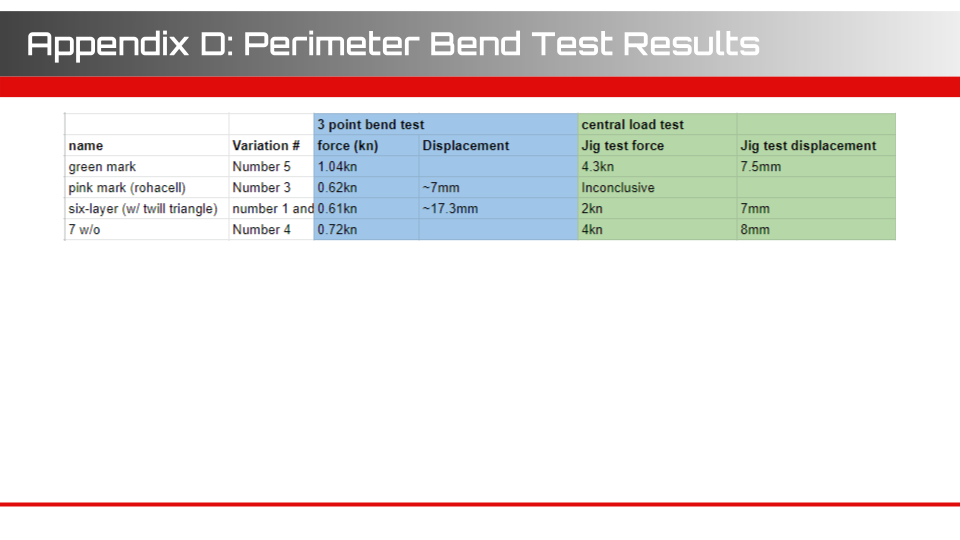

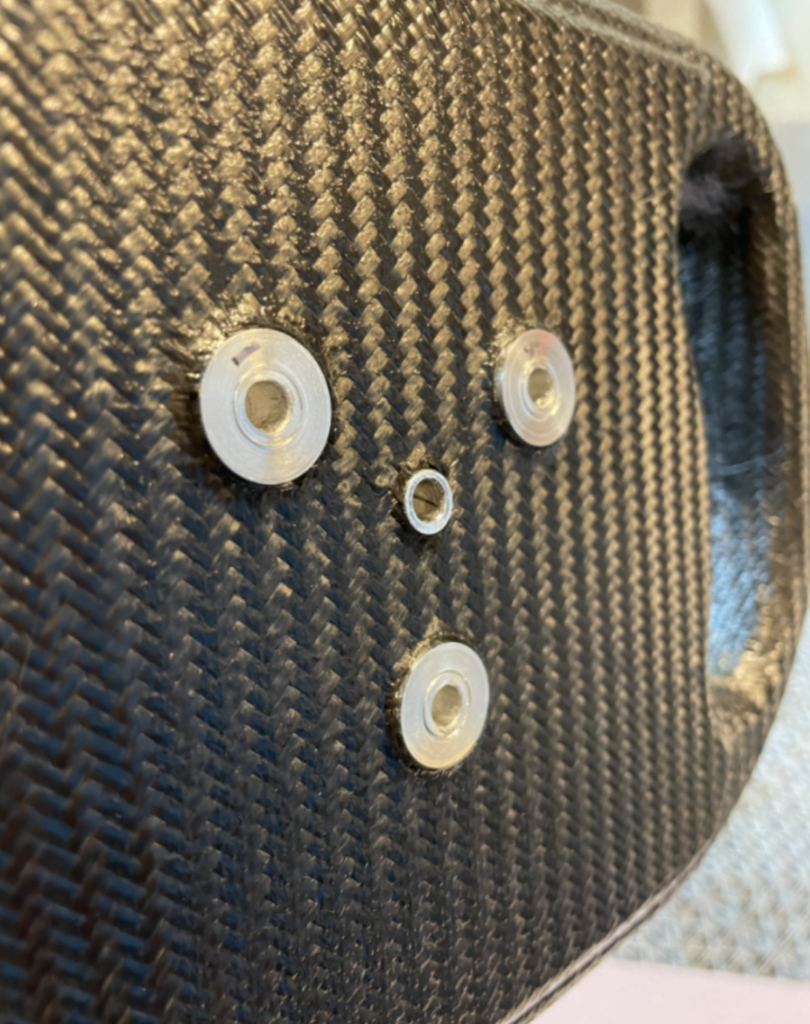

This being an entirely novel project for the team, we started by first validating whether sufficient strength could be achieved using our proposed design of co-curing machined aluminum inserts inside the rear face of the steering wheel. We produced numerous test layup panels with inserts and performed both torsional and perimeter bending tests to characterize the strength and stiffness of the wheel enclosure’s mounting to the steering column quick connect:

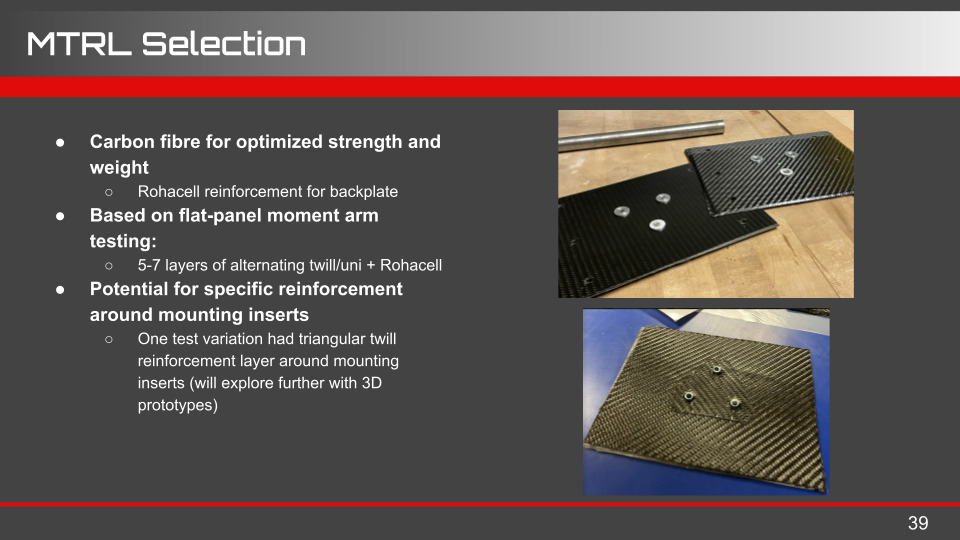

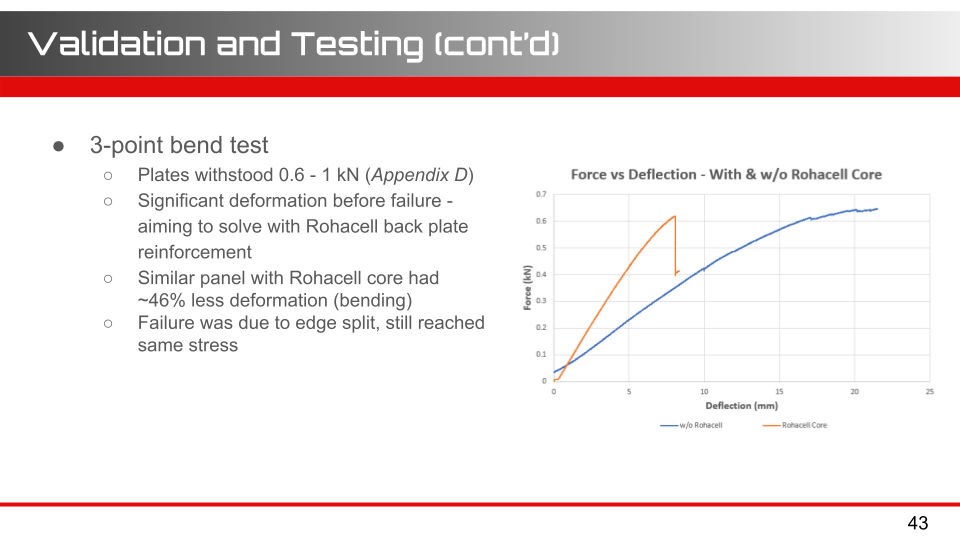

I was pretty confident that our test panels would not be sufficiently stiff in out-of-plane-bending, which would be the load case when a driver slams on the brakes and puts their weight into the wheel with their hands. Due to this we made a 1/8″ rohacell-cored plate, which would increase the rear face’s bending stiffness significantly. Below are some key slides from the design review presentation that myself and Jonas gave regarding the results of our tests:

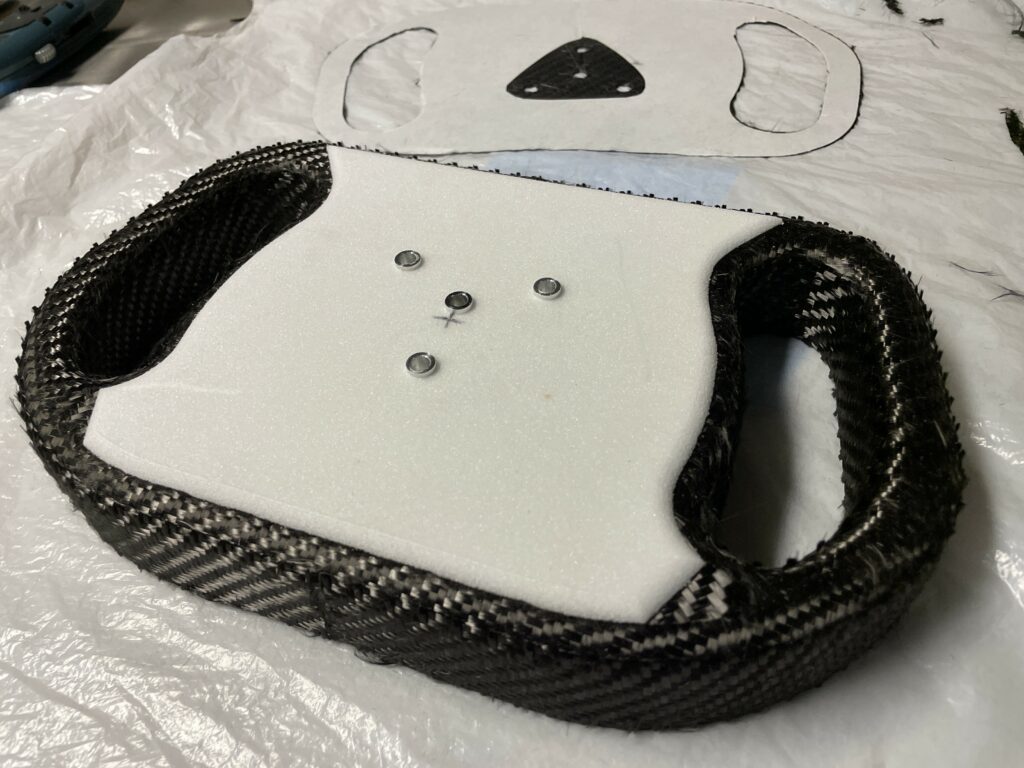

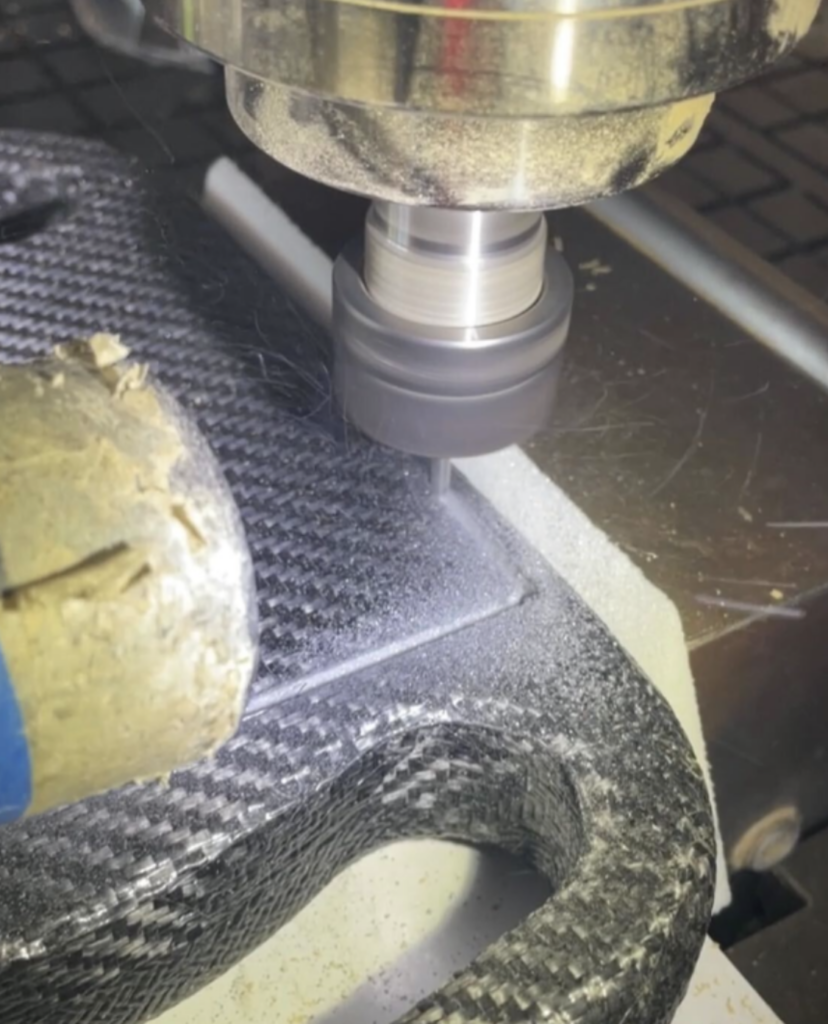

Based on these results, we began wheel manufacturing based upon Indigo’s mechanical design. The first phase involved manufacturing a test layup which would later serve as a dummy wheel and practice wheel for driver egress where the wheel can get tossed to the ground. The first step was to machine an internal rohacell form, which we did on our CNC router:

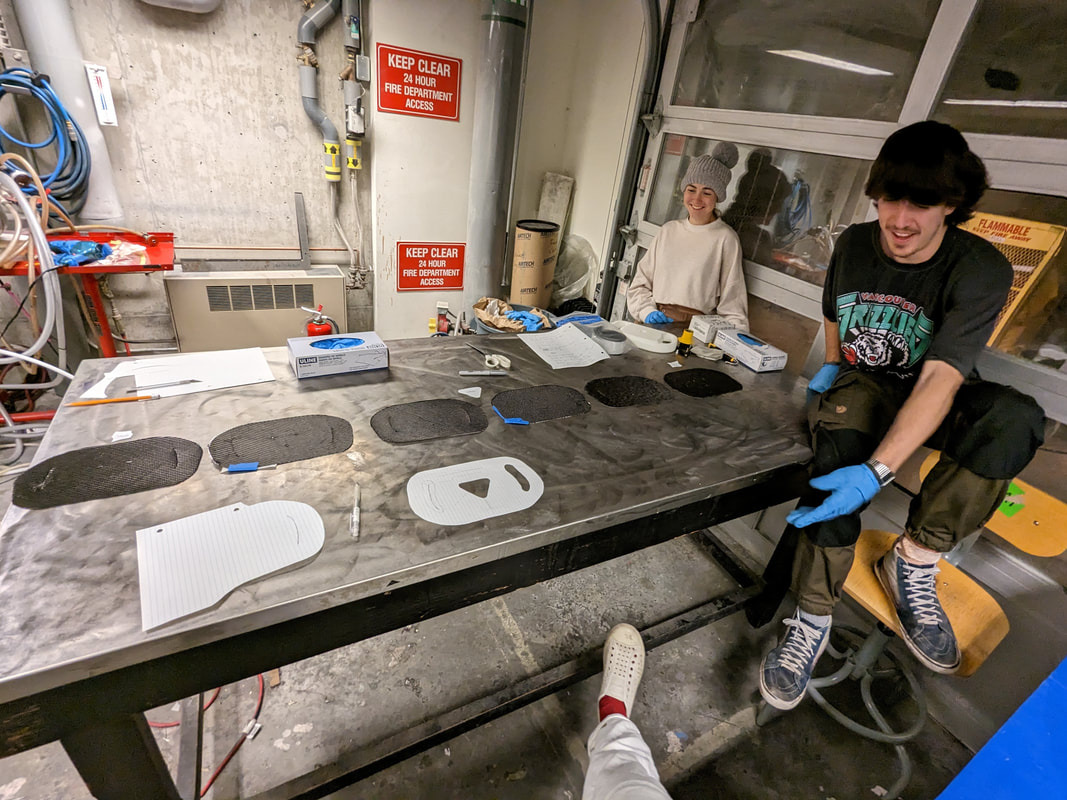

We wanted the layup to maintain a high level of process consistency as we’d be destructively testing this part to inform our second layup. Rather than cutting out carbon plies by hand, we used the wheel geometry from Solidworks to create several flat patterns to cut out using a drag knife from a Cricut cutter that I lathed down to fit inside our CNC router’s spindle. We opted to use 6 plies of twill across the whole surface (45-45, 0-90 alternating) and an additional ply of 0-90 oriented weave on the back face layer in which the rohacell sandwich panel is under compression. This choice was directly informed by our small panel testing previously. The layup began:

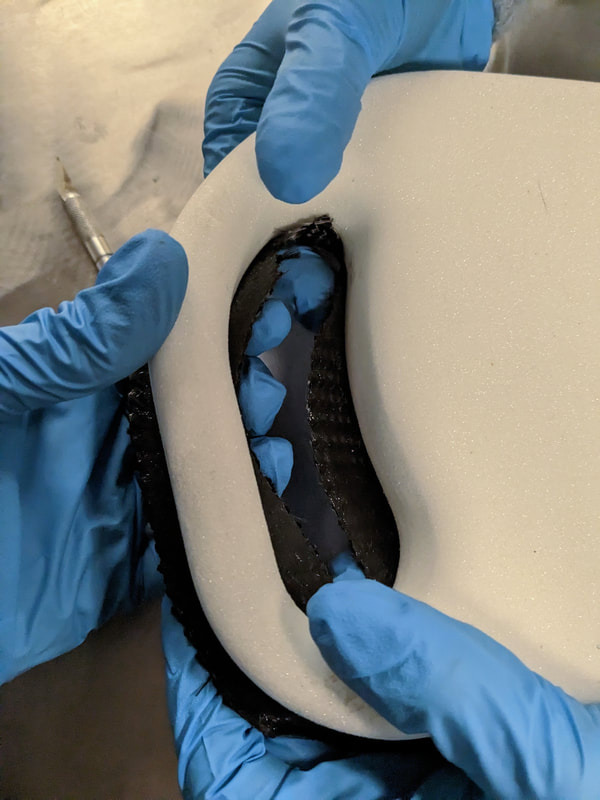

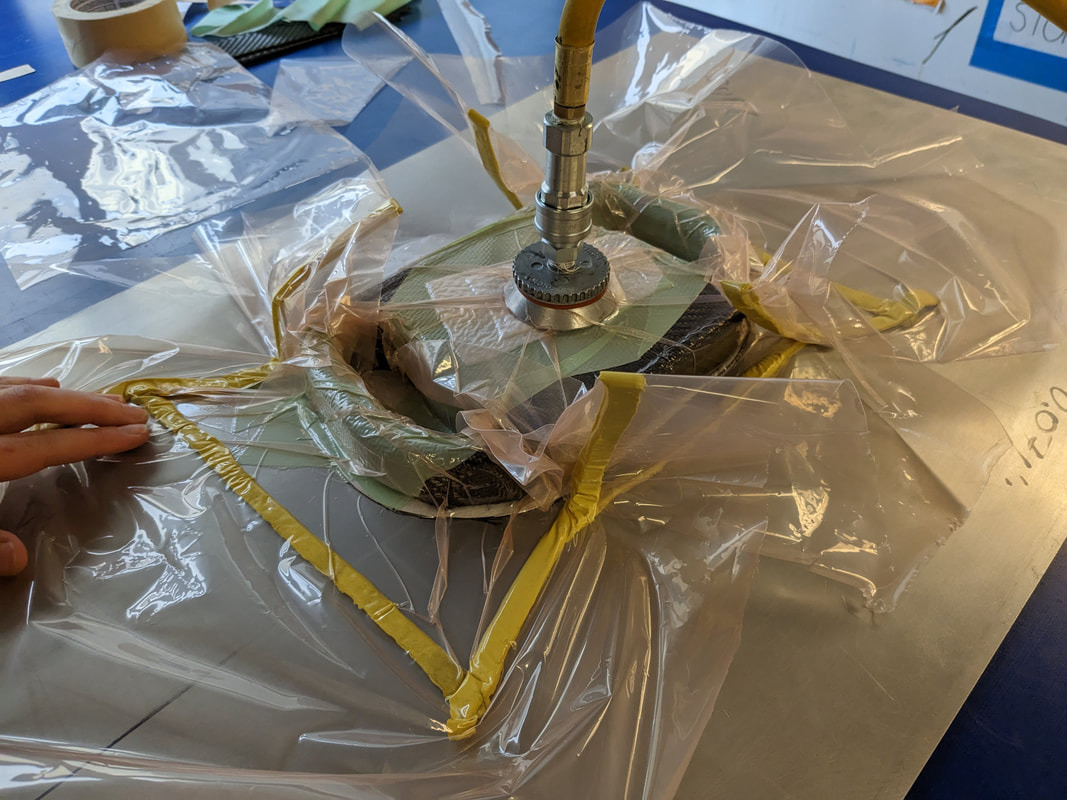

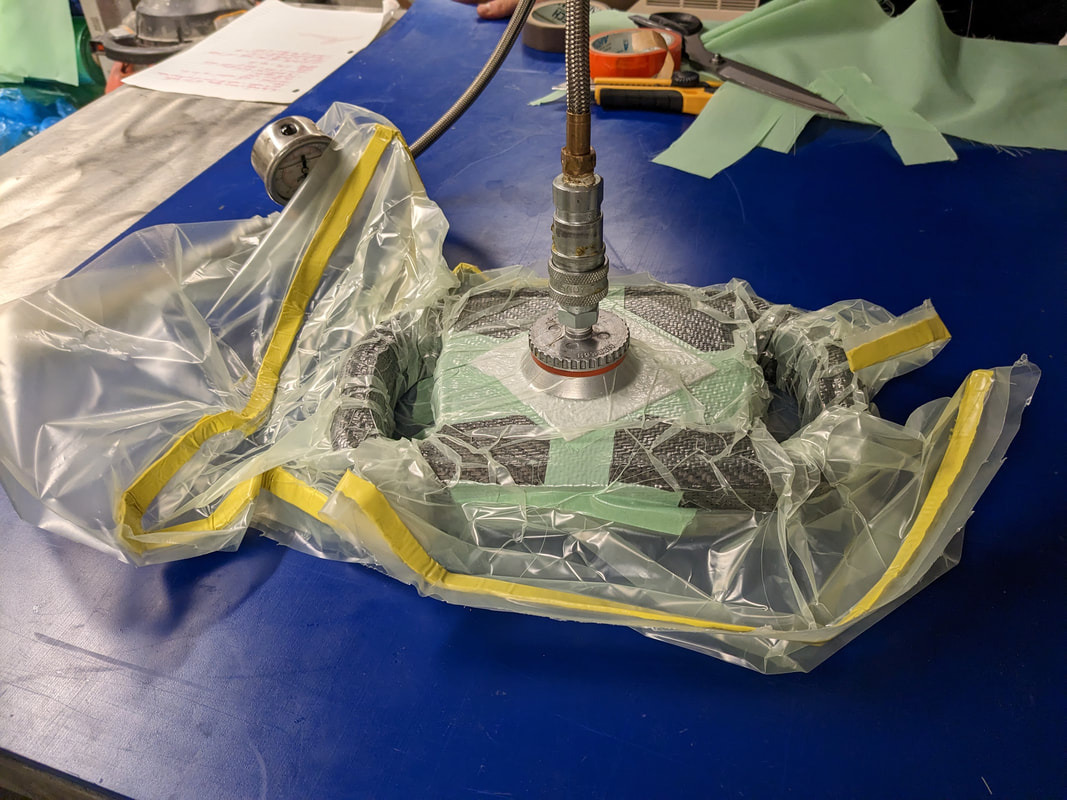

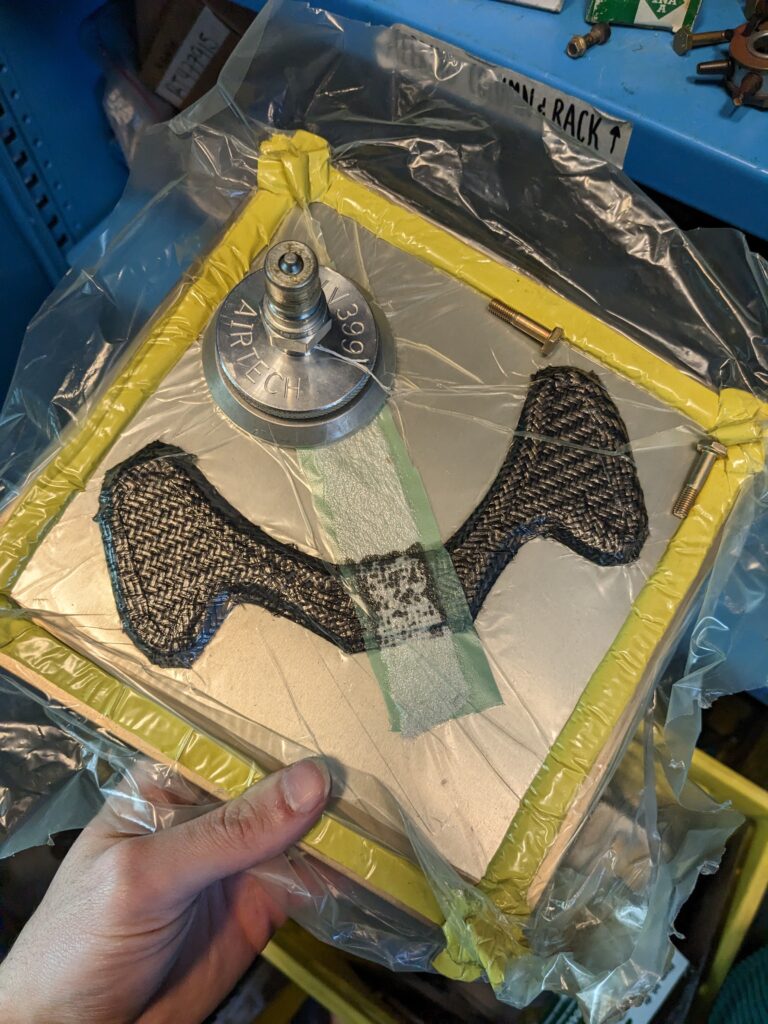

Our strategy was to overlap plies by ~6mm between each of the front, back, and side sheets per layer for increased strength and to reduce the probability of any fault lines along the part. As we soon discovered, this let to stacked overlaps which added a lot of bulk to the layup, so we opted to vacuum debulk between plies:

Our strategy with vacuum bagging was was to maximize airflow from the handle pockets to the nozzle without adding too much breather cloth, as the breather would likely soak up excess resin, leaving our part dry and thus weak. In place of breather cloth, we used strips of peel ply around the sides, back, and into the handles.

The cure was good, with decent wetting of the fibers. Surface finish wasn’t pretty due to the peel ply used to encourage some airflow paths, but this was expected. The main negative result is the pinched and raised carbon lips around the perimeter of the wheel, due to having excess overlapped carbon in the corners.

Surface finish was also poor due to the strips of peel-ply used, so we hoped to find an alternative. Electrical implementation was smooth with a little filing of the wheel opening, and the display was tested, as well as the contacts for our buttons and rotary encoders. As you can see, the structure of the wheel does not rely on any of the electronics or faceplate, and this was important to us so that we can easily swap electrical packages and not worry about the structural integrity of our wheel.

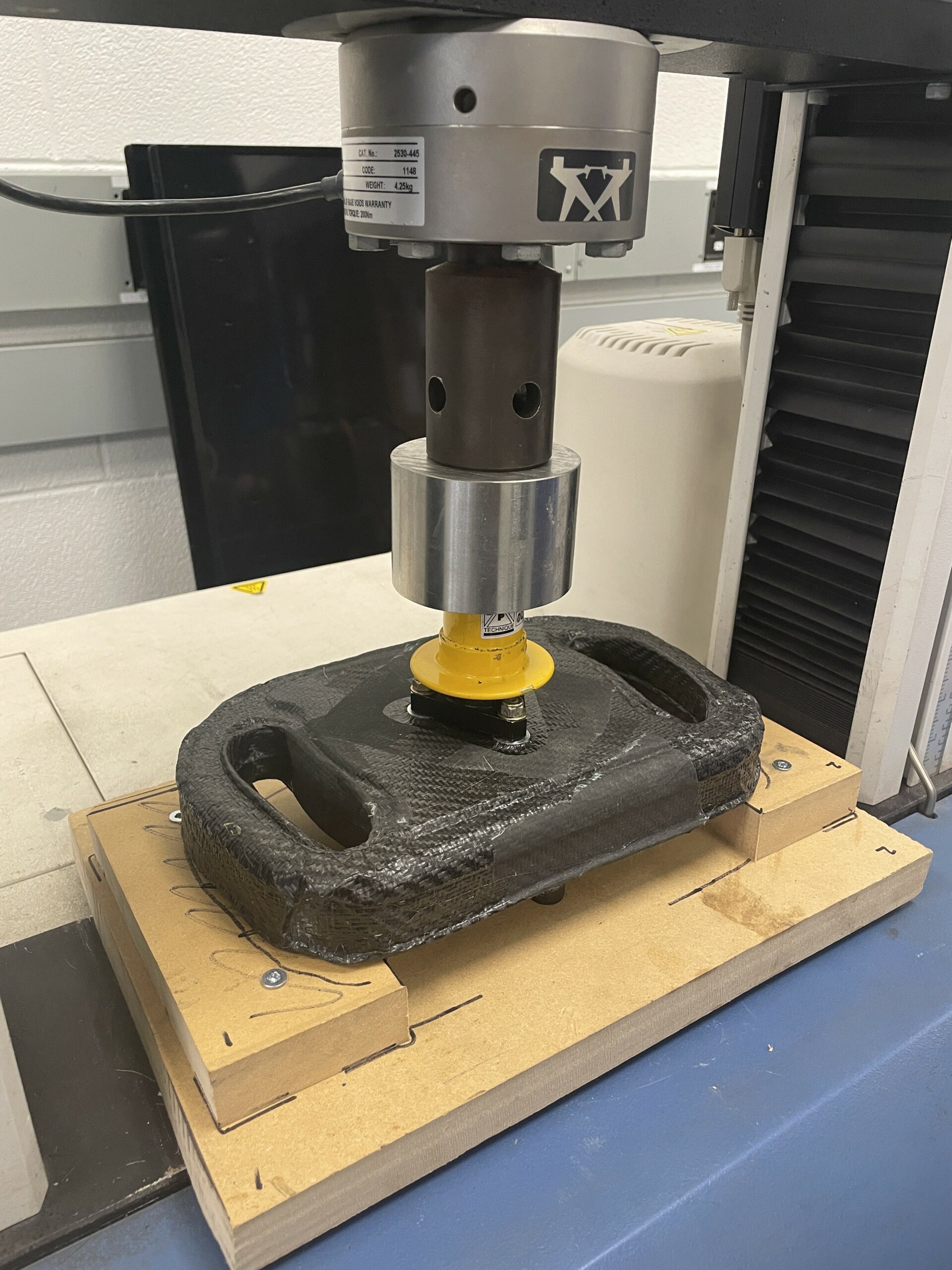

We wanted to simulate the stresses from a pair of hands gripping and twisting the wheel, so we built a jig to torsion test the cured wheel, using ratchet straps in place of hands. We also simulated the previously mentioned out-of-plane bending load case as shown below:

After this prototype exceeded our strength expectations (with a safety factor of ~4), we opted to decrease the number of layers to 4 to reduce ridging and further optimize the strength to weight ratio. As mentioned earlier, our final steering wheel had six plies all around, with one additional layer and a Rohacell backplate on the rear face. We chose the fibre orientation of our layers to line up with the stress concentrations tangent to the rear bolt circle at 45 degrees and 90 degrees. We also added release film folded around the edges of breather cloth instead of peel-ply to encourage airflow, which worked better and we noticed minimal breather cloth saturation with resin. We manufactured our final steering wheel taking into consideration all of the issues and notes we had during the prototyping phase. The result was a much-improved surface finish, zero ridging, and perfect insert alignment for mounting.

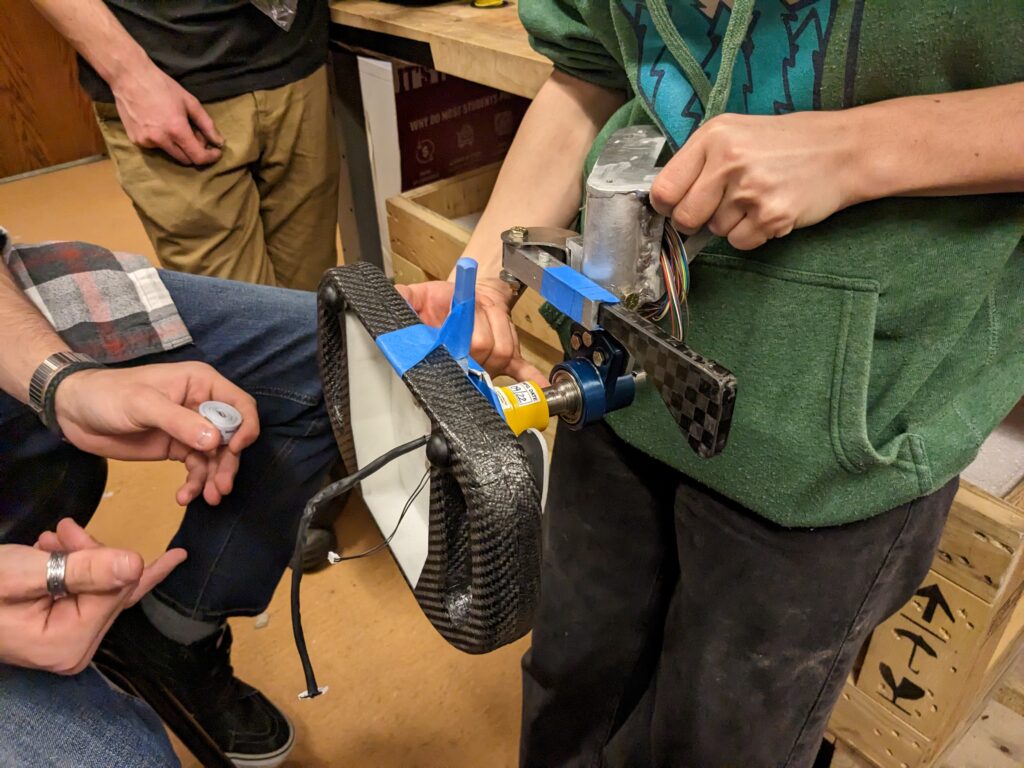

We fitted all electrical and installed buttons for paddle-shifting at the back, as well as DRS and Electronic clutch engagement at the front. All the parts, including the paddle shifter layup, hand clutch, and steering column mount came together of over the course of a couple very late nights:

And finally, after some paint, an internal waterjet cut retaining ring and gasket for waterproofing, a comprehensive proof loading, and more than a little love, here is the final wheel which came with us to competition! Exploring other teams’ designs, we found that we were one of only 4-5 teams (out of 120!) who had developed a composite steering wheel with integrated electronics. This wheel is planned to be used for several years to come – we have left several buttons and rotary encoders unused for future feature development on the electrical side, and with robust process development on the materials side we can remanufacture much quicker given how much we have learned through this ambitious project!

Project Outcomes

30%

Reduction in system mass from previous season’s wheel

450%

Increase in driver-interactable buttons and rotary encoders

Complete

Elimination of bridging, surface finish defects, and ridging due to overlap and insufficient debulking

Massive

Improvement in team composites and wheel design capacity!

Skills and Learning

•••••

Composites layup process design and optimization

••••◦

Stress test design and jigging

••••◦

DFMA

••••◦

Structural optimization

Leave a Reply