When I was tasked with coming up with a way to make this year’s seat, I had the inspiration to use beads and resin to make a custom mold around our main driver’s body, and then use an iPhone with LIDAR to scan the 3D geometry of the mold impression so that we could easily manipulate the geometry in an organic modelling platform like Blender.

This inspiration came completely out of my absolute fascination with the iPhone’s application of LIDAR combined with pictures to create textured 3D models for use in visual effects – a subject that provides many of my inspirations!

Later, I found out that this is pretty much exactly how Lewis Hamilton’s seat was molded by Mercedes F1 team (albeit with more expensive and performant everything).

We ended up foregoing this seat for competition, but I still wanted to showcase the idea and prototyping efforts. Below you can see how we made the styrofoam ‘beads’ using some discarded insulating organ storage containers from the UBC hospital, then mixed the beads with liquid resin:

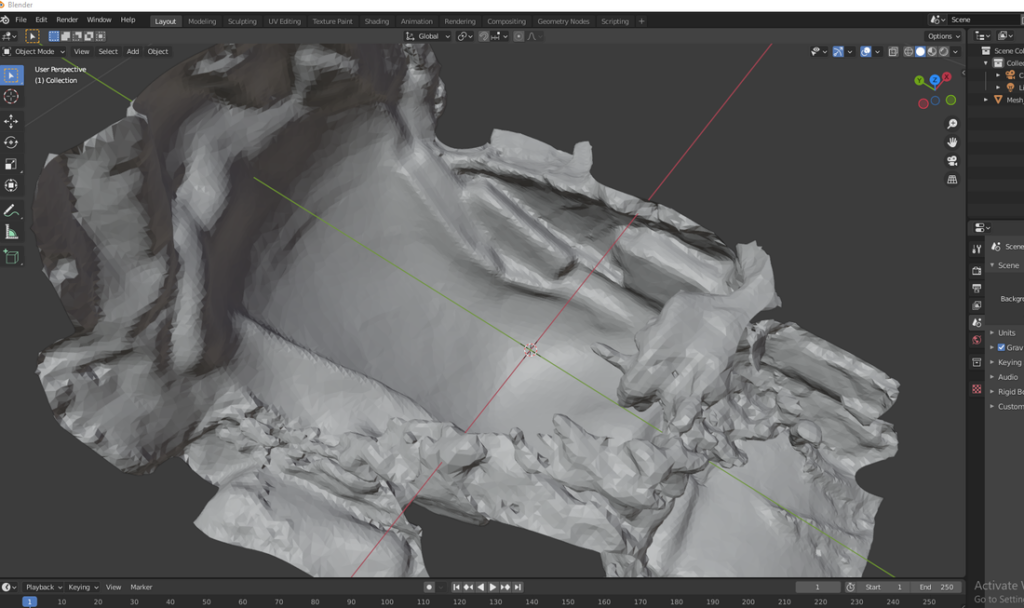

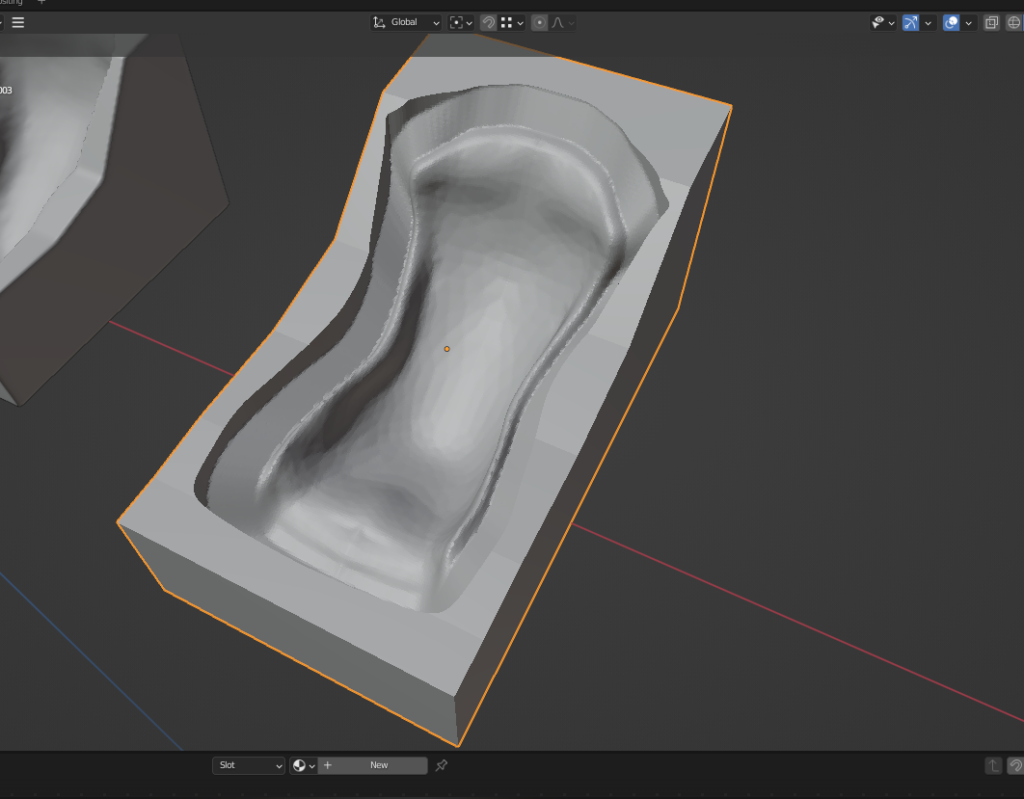

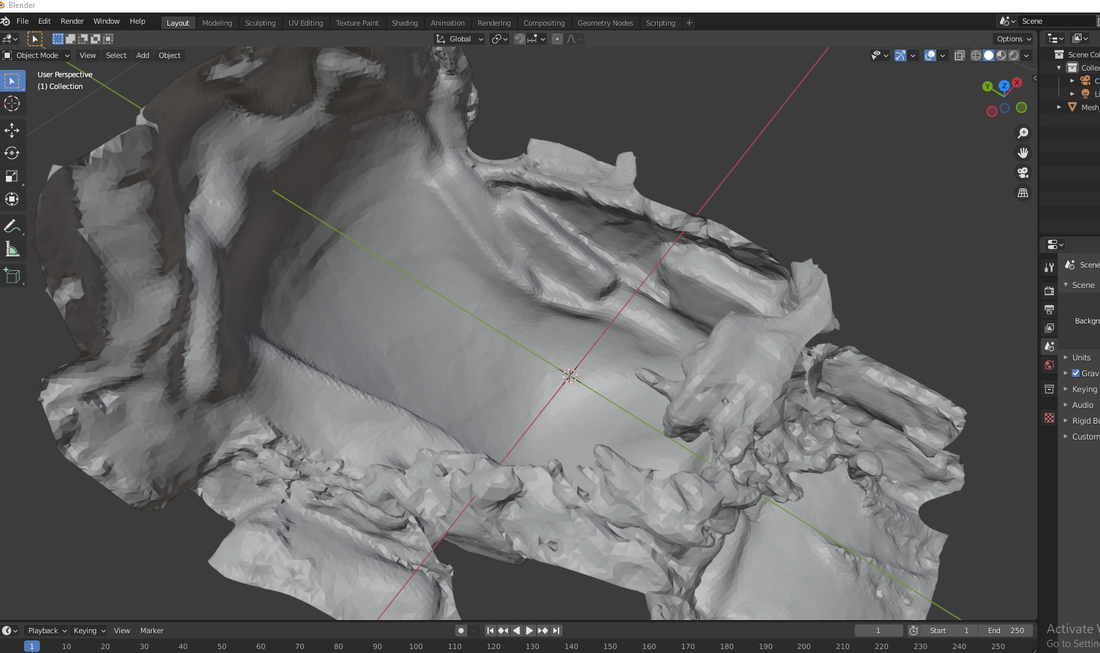

As you can see, we put the resin-bead mixture into a bag and had our main driver, Can, sit inside the car to give us an impression to photoscan with the iPhone – below you can see the scan result, imported into blender, and cleaned up for a final mold geometry:

Project Outcomes

Creation

of a novel process for scanning the geometry of ergonomic fit items for the team

Skills and Learning

•••••

Moldmaking and ergonomic impressions

••••◦

Blender for organic geometry surface modelling

Leave a Reply