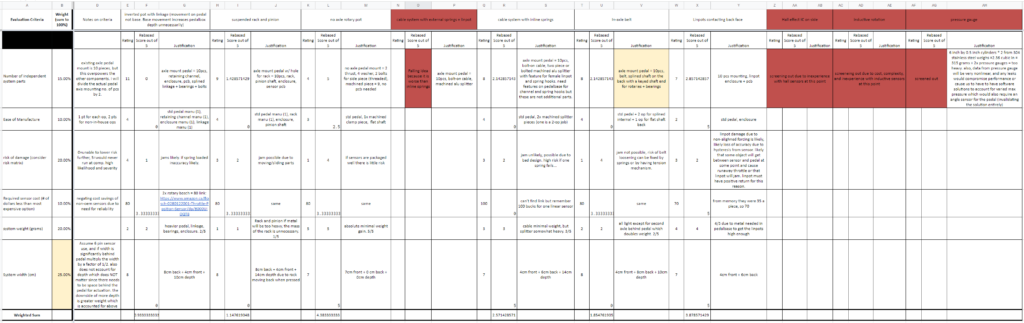

Anticipating ownership of the pedalbox project for the 2022-23 season, I’ve set a goal for us to not only have fully electronic throttle control, but also a lighter, simpler, compression molded carbon fiber pedalbox design. Most of my work so far has been on developing a good system for sensing throttle pedal position, and you can see the design generation and weighted decision matrix I created below to asses many options:

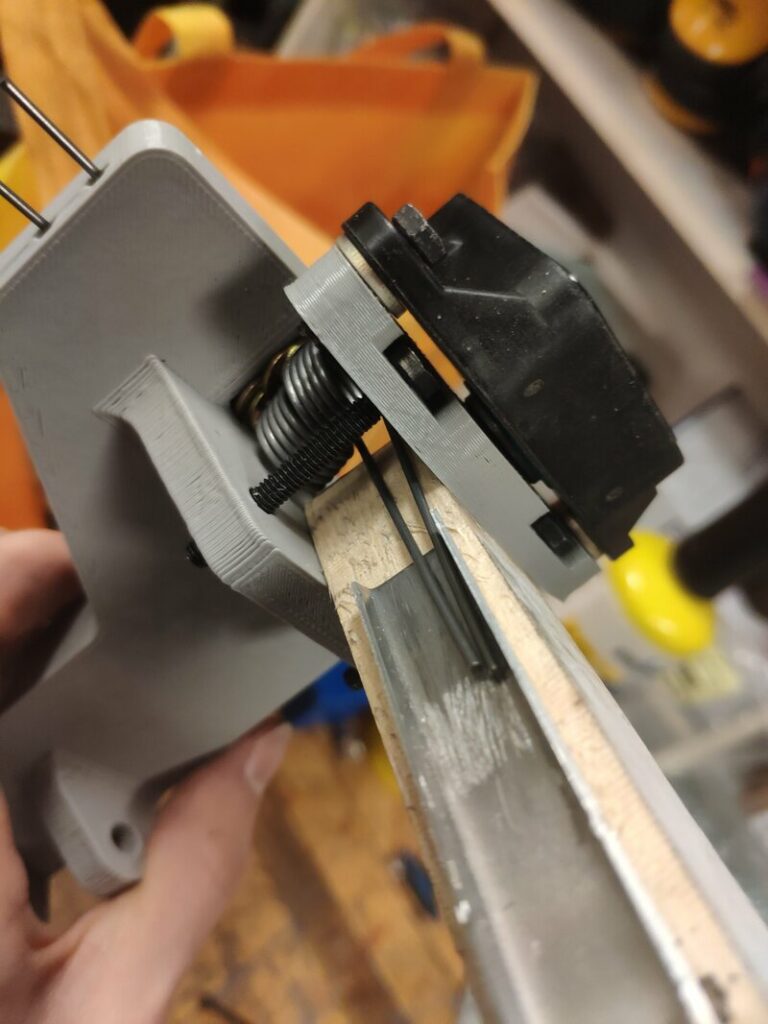

I designed and created a prototype version of the pedalbox which uses a flatted shaft and a rotary encoder in the form of an extra Bosch throttle position sensor we had. The bolts which hold the throttle pedal rotation axis tight also function as the positive and negative stops, simplifying and adding lightness. I quickly made this pedalbox in a day using 3D printing, a lathe, and a bandsaw:

There are several improvements to make to this design – the spring mechanism for the throttle pedal in particular needs refinement, and the printed base is more of a overall space claim than a detailed design given uncertain floor geometry and mount points. However, I am confident in the design concept overall – it benefits from simplicity, compactness and helps reduce some weight that the rotary encoder inevitably adds. After much research, I settled on these sensors for our new pedalbox for a final design. They are significantly smaller and come in a 6 pin option with two mechanical potentiometers per sensor which allows us to only run a a single sensor at competition while meeting regulations. This ensures redundancy in case of a single sensor failure with both 0-5v and 5-0v signals read off of the two potentiometers.

Given my move to become Materials and Manufacturing Subteam Lead the following year combined with the shift to a monocoque platform, we ended up shelving this more radically different design and went with something ultimately very similar to our past designs.

Project Outcomes

Creation

of a tested blueprint for future throttle-by-wire development as the team matures

~15%

weight savings relative to past aluminum pedalbox designs, accounting for the weight of a basic compression molded carbon fiber geometry and selected rotary encoder

Unlocks

Potential for future development of engine mode control, traction control algorithms, active aero features, and more

Skills and Learning

•••••

Engineering conceptual analysis and complex decision-making

••••◦

Rapid prototyping for proof-of concept development and testing

Leave a Reply