With the 2023 Monocoque, our previous method of welding some tubes onto the frame as a steering column mount wasn’t going to work.

After numerous prototype mounts had been produced and failed well before target loads, I was assigned this project by my team captain. We needed a solution that we could manufacture relatively quickly that was lightweight and rigid, and ensured rules compliance by staying out of the way of the cockpit template that must pass through the interior of the chassis where the drivers’ legs pass through.

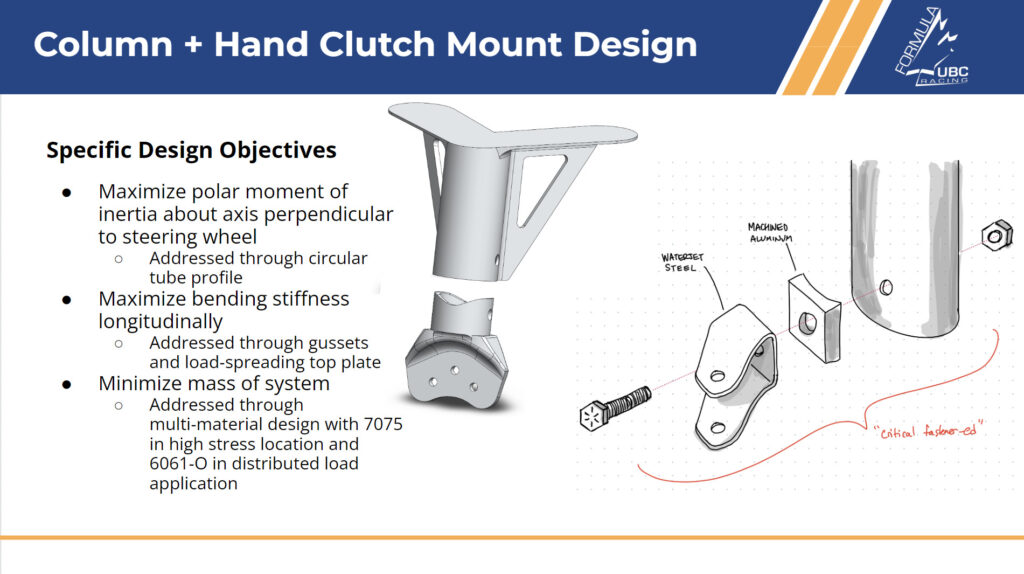

To solve this problem, I referred back to my solid mechanics first principles and based my design around these. Welding had been dismissed before due to the fact that the aluminum will be in an annealed state to some extent after welding. However, I identified that the most stressed elements of the system could still be heat treated using a two-part design:

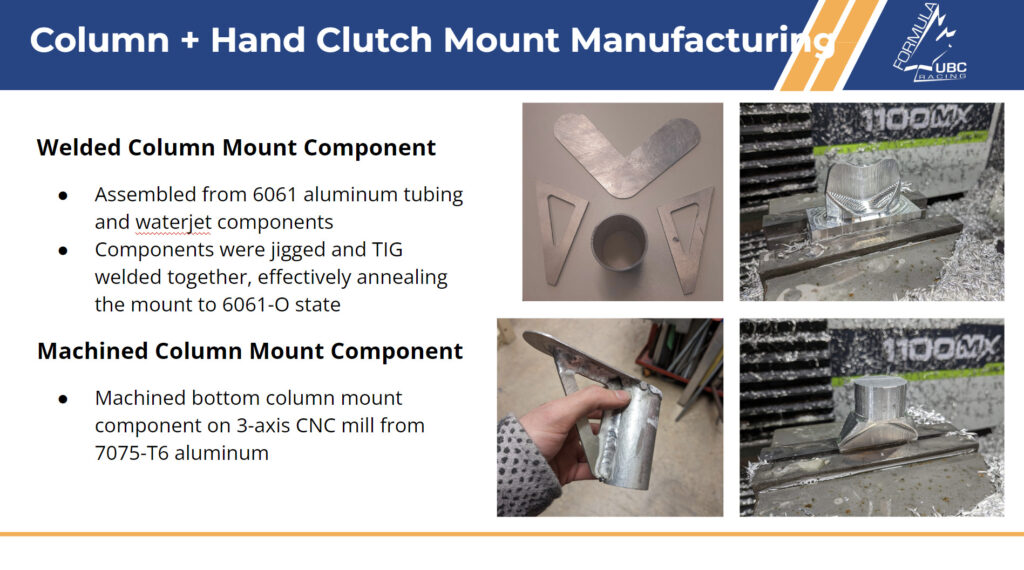

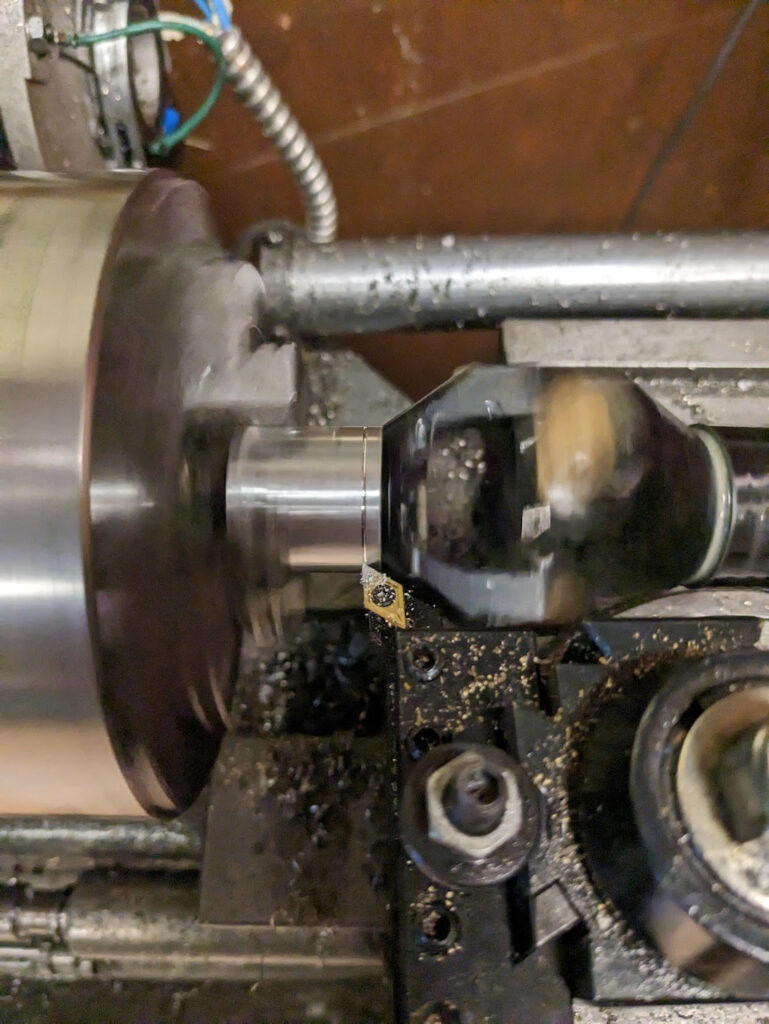

Next, a summary of column manufacturing, which tested my aluminum tig skills in the tight weld joints!

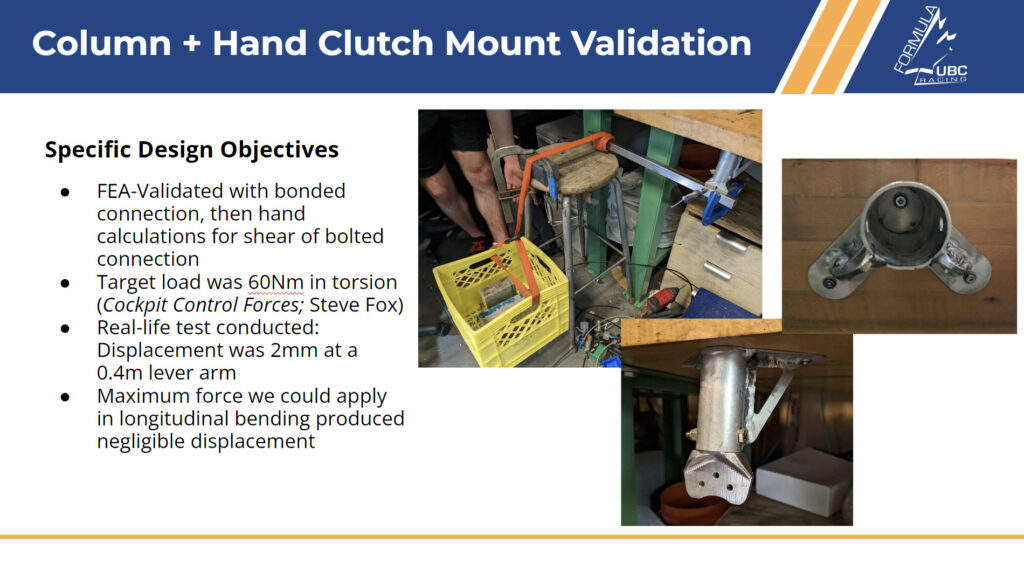

Below is a summary of how I validated my design, which doesn’t include how I had some beefy teammates wrench on the mount with all their might afterwards and it stood up fine!

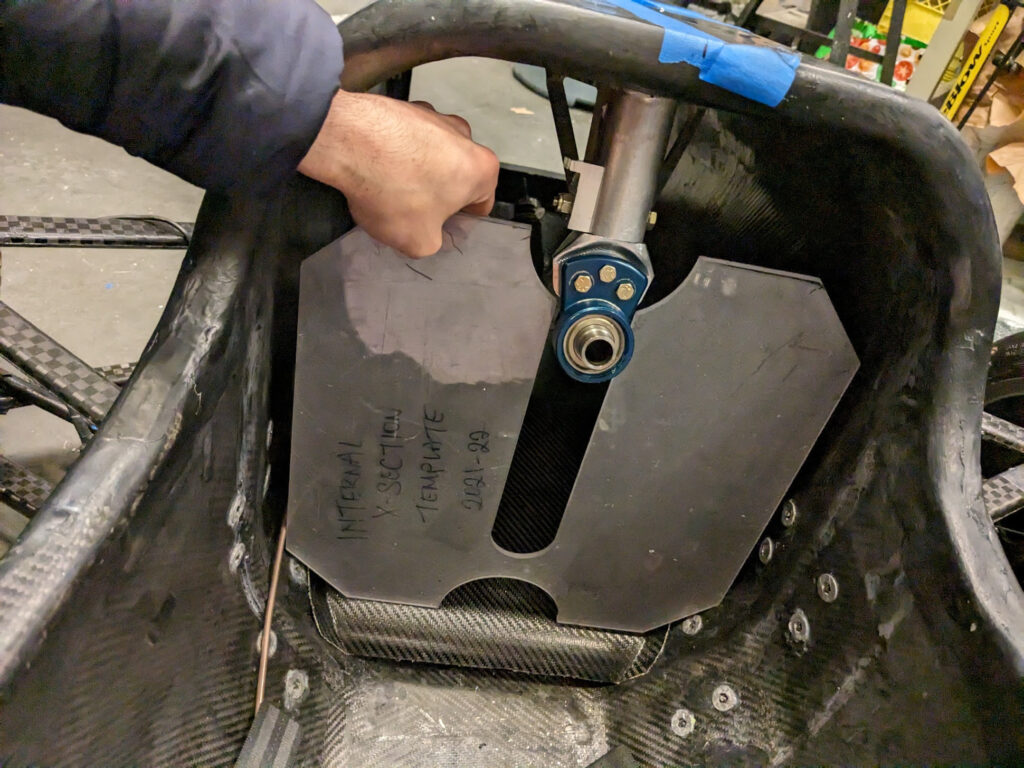

Finally, we come to mount installation, which the Chassis subteam helped out with by installing threaded inserts into the moncoque ceiling for me to bolt my mount to after painstaking positional measurements.

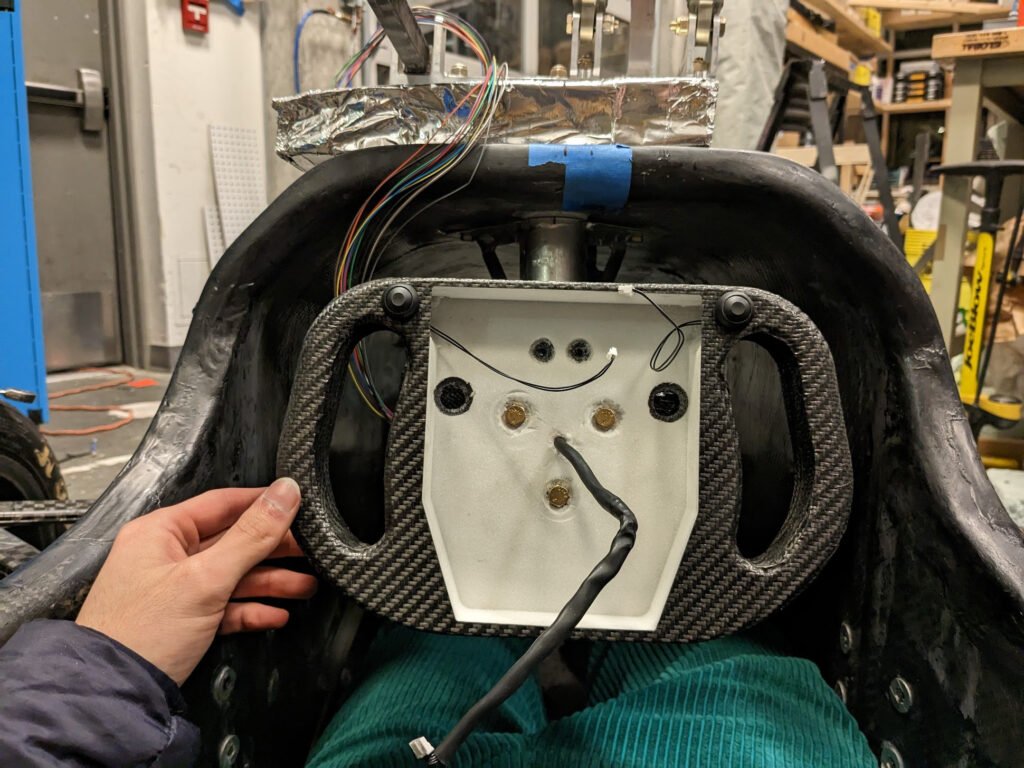

And here is myself checking with our steering wheel:

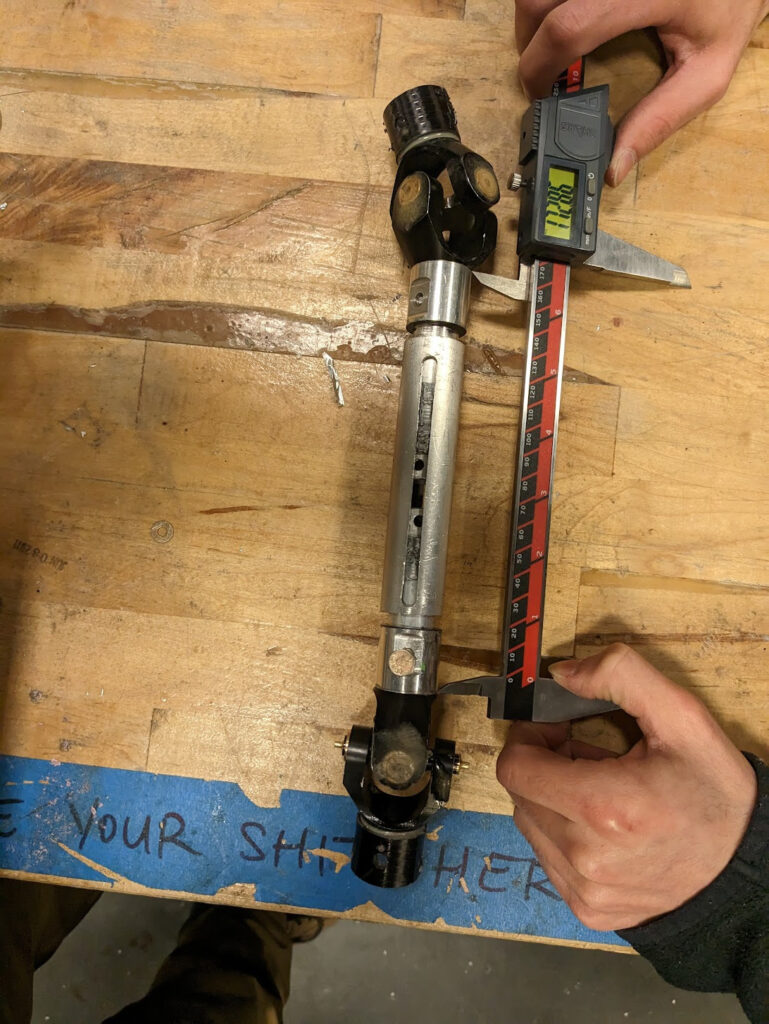

Next, it came to making the actual steering column, which I also took on:

Above the steering column is ready to bond, with backup critical bolts and nylock nut holes for rules compliance.

Design Outcomes

Minimal

displacement of 2mm at a 0.4M lever arm at target load

150g

Extremely light column mount

Includes

Hand clutch mount and passes critical fastener rules

Skills and Learning

••••◦

Solid mechanics and design optimization for targeting stresses efficiently

••••◦

FEA, robust hand calculations to validate designs

••••◦

Aluminum TIG welding

••••◦

CNC machining and workholding

Leave a Reply