Here I’d like to highlight some of the learning and research I’ve done to develop some of my own CNC and 3D printers. I did this at first because it was cheaper, but as I learned more and more, I felt so fortunate to have build my own rather than just buying something ready-made. Especially with the 3D printer, I’ve had to troubleshoot just about every imaginable issue, teaching me invaluable skills along the way.

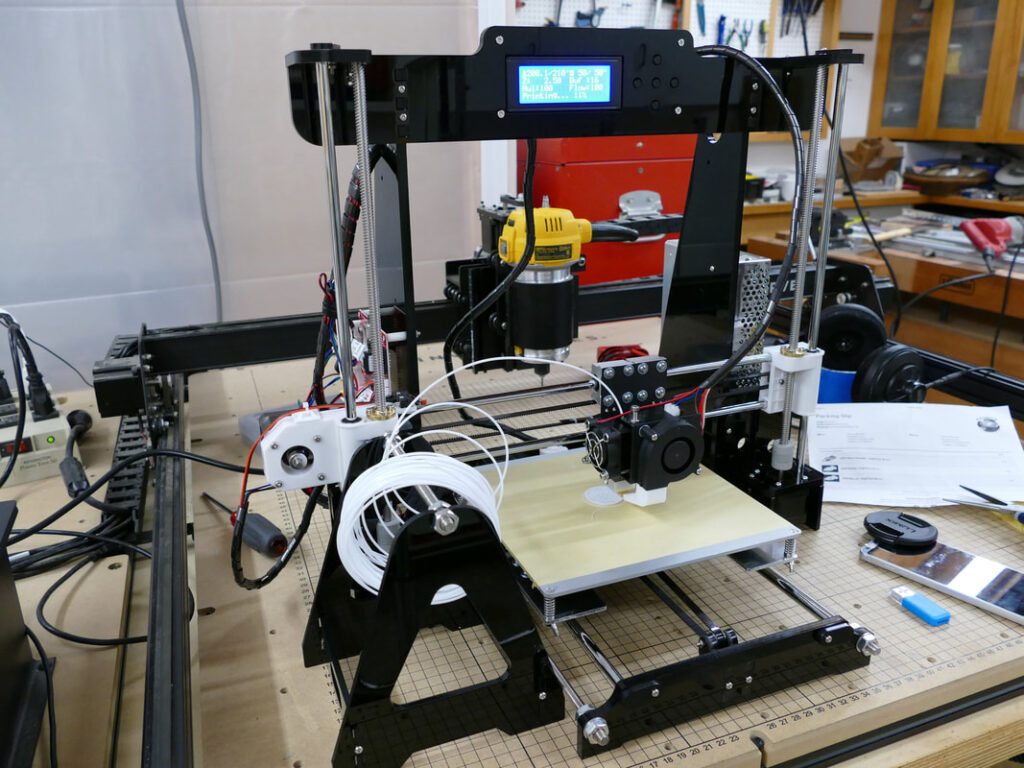

Personal 3D printer, 2017-2022:

This is the 3D printer I have designed and built from aluminum extrusion and PETG printed parts to offer 220mm cubed build volume, all-metal extruder, and the structural rigidity to print at 300% the speed of similarly priced printers. It started life as a cheap AliExpress clone printer, but has since received upgrades in virtually all aspects.

I rebuilt the frame from PETG and aluminum extrusion, doubled the bed size and xy work area, replaced the power supply and fitted higher-current mosfets, replaced the extruder with an all-metal clone that can print higher temperature materials, fitted rubber decoupling mounts to all motors, and poured a concrete base to resist vibration when the print head is accelerating quickly. I’ve also upgraded to a build of Marlin firmware I’ve modified, and added a Raspberry Pi with octoprint and a camera for remote operation.

Through this project, I have gone from zero knowledge of 3D printing to a very sound capacity. I have taught myself evvery single setting of Cura and PrusaSlicer, done countless calibration tests to optimize the machine’s profiles, and become much better over the years at design for additive manufacturing (DFAM) using FDM printing.

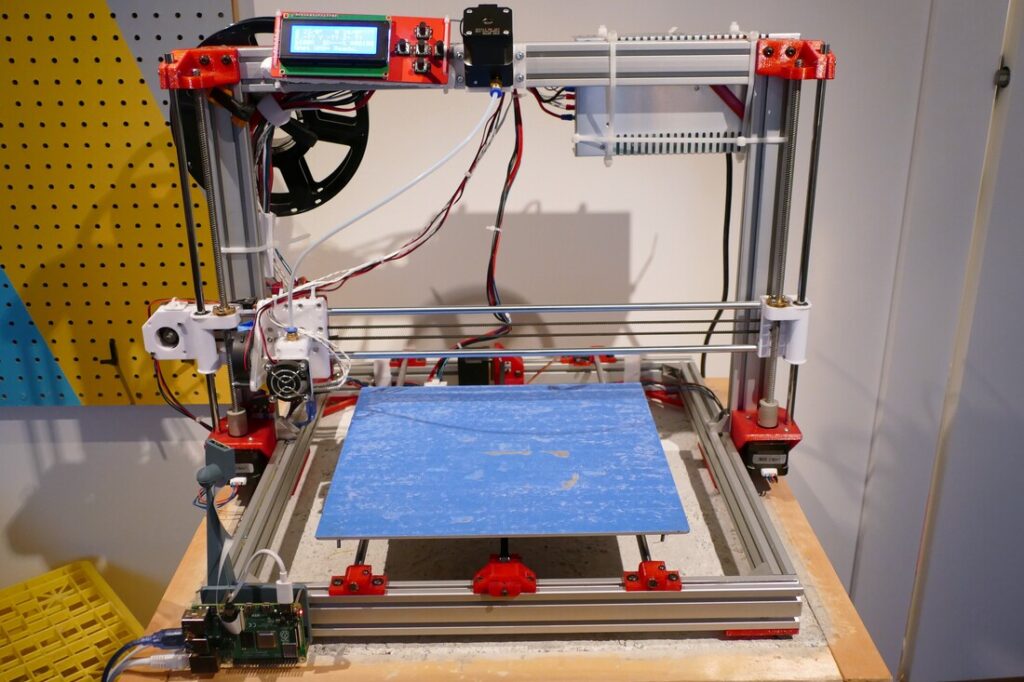

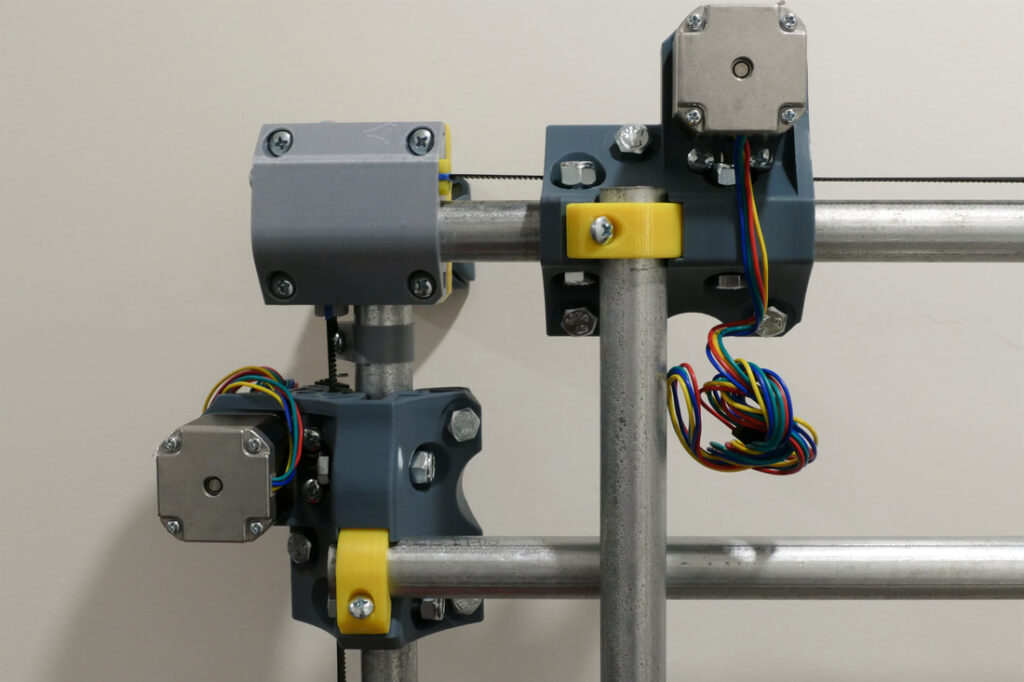

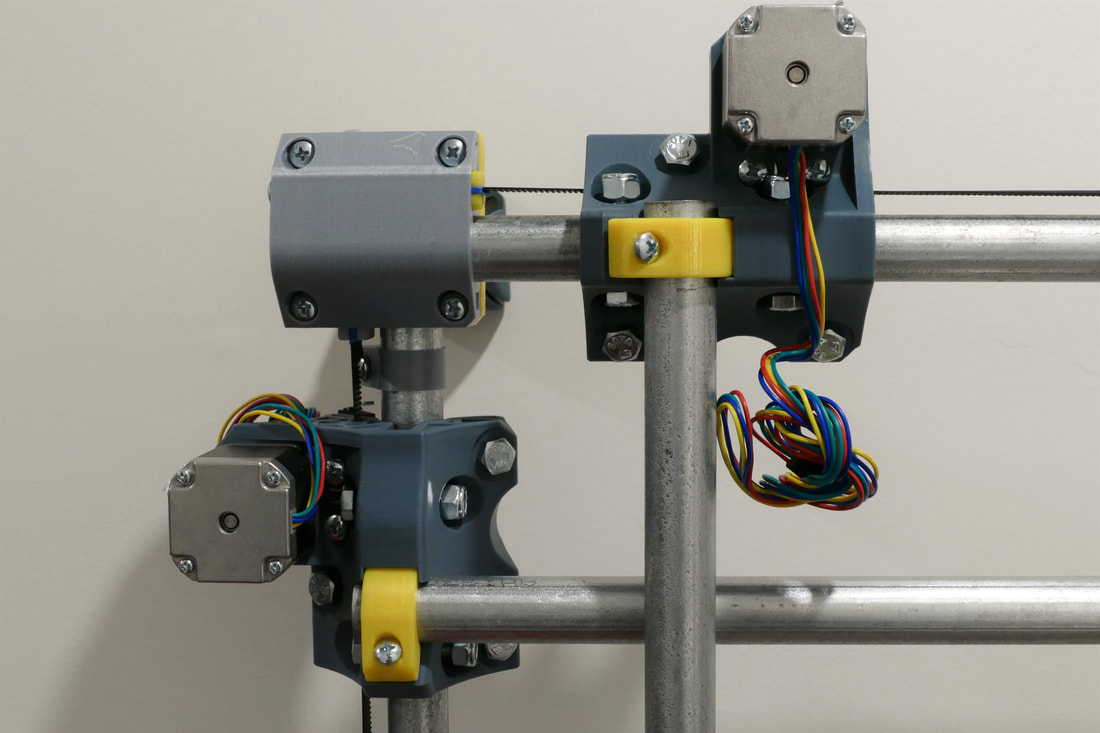

MPCNC 3D printed CNC Router Frame, 2020:

Building off of the open source MPCNC platform I worked on a large-format CNC router made from 3D printed parts and steel conduit. My goal was to have swappable toolheads for machining aluminum and wood, plotting vinyl decals, cutting fabric patterns, and swappable pens for a large-scale printing platform. In the end, I repurposed this gantry for use in my third year Integrated Engineering Capstone Design Project: ReMold.

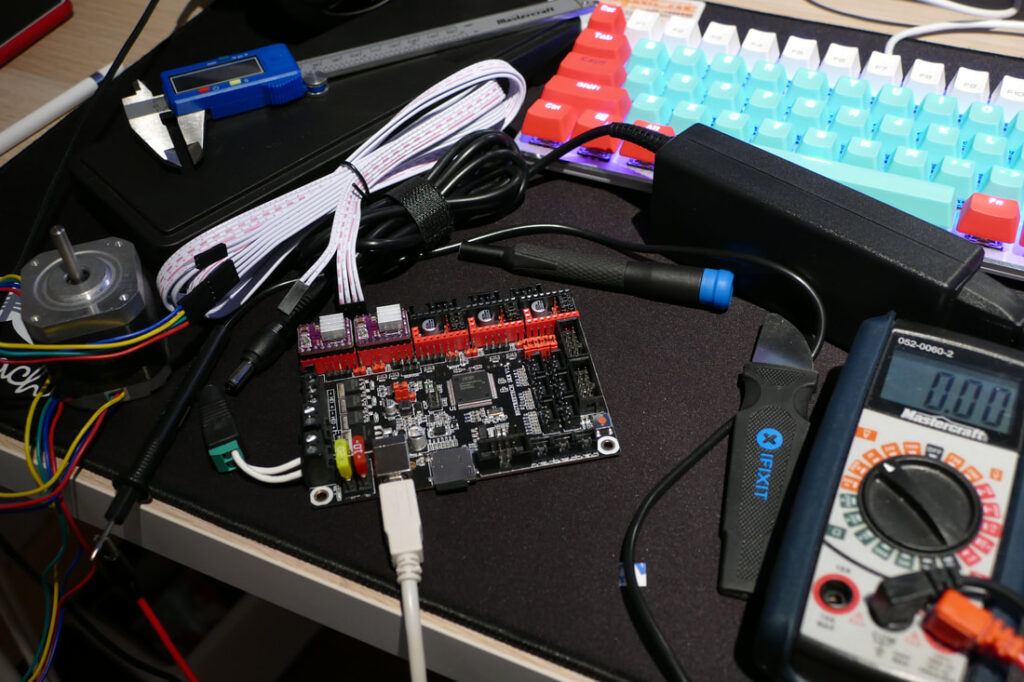

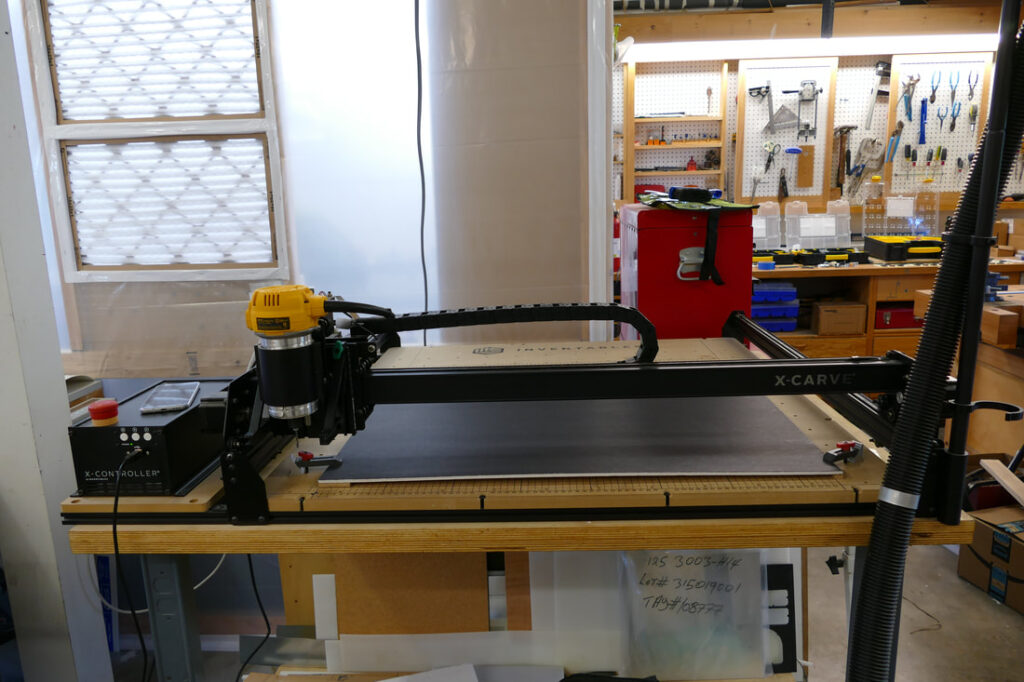

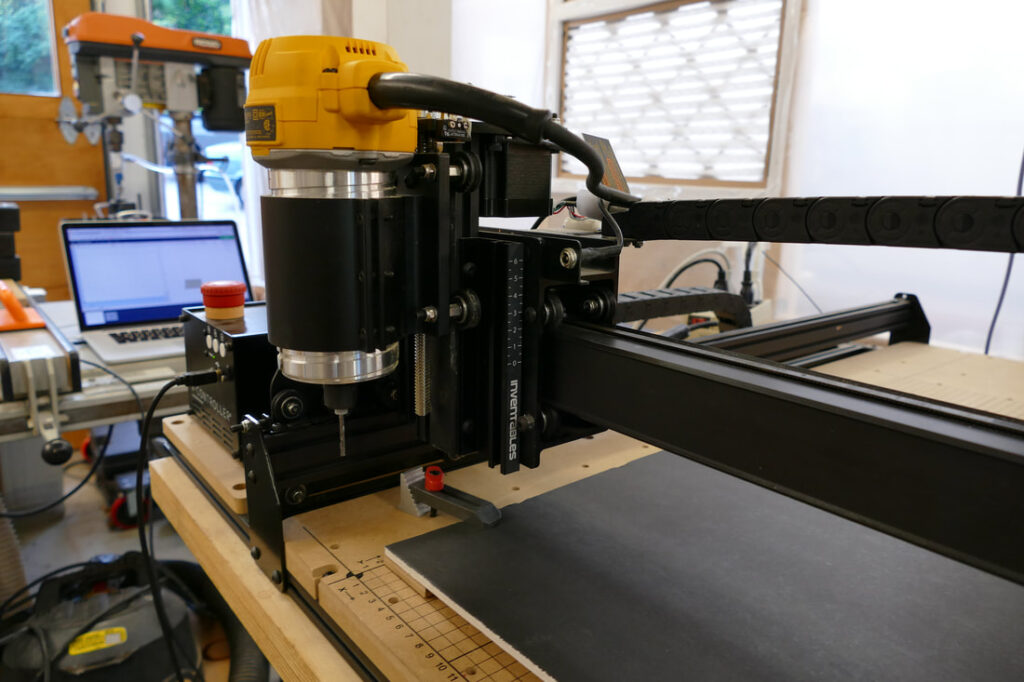

X-Carve CNC Kit, 2017:

This was the first CNC router I used, which I built from a kit. Using this machine I begun learning Solidworks and HSMWorks when I was 16. Having never even seen a CNC mill in real life, this was a fantastic project for me to immerse myself and learn about CAM. I used this machine for personal projects and my work at HJMG DesignWorks over the following 6 months.

Leave a Reply