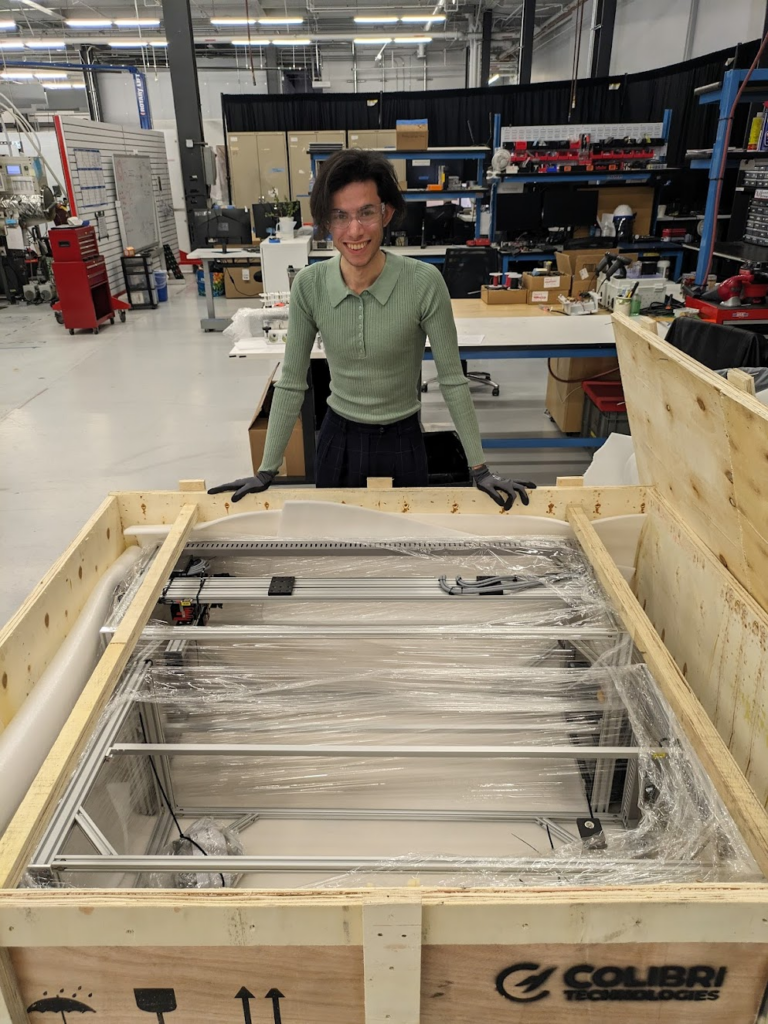

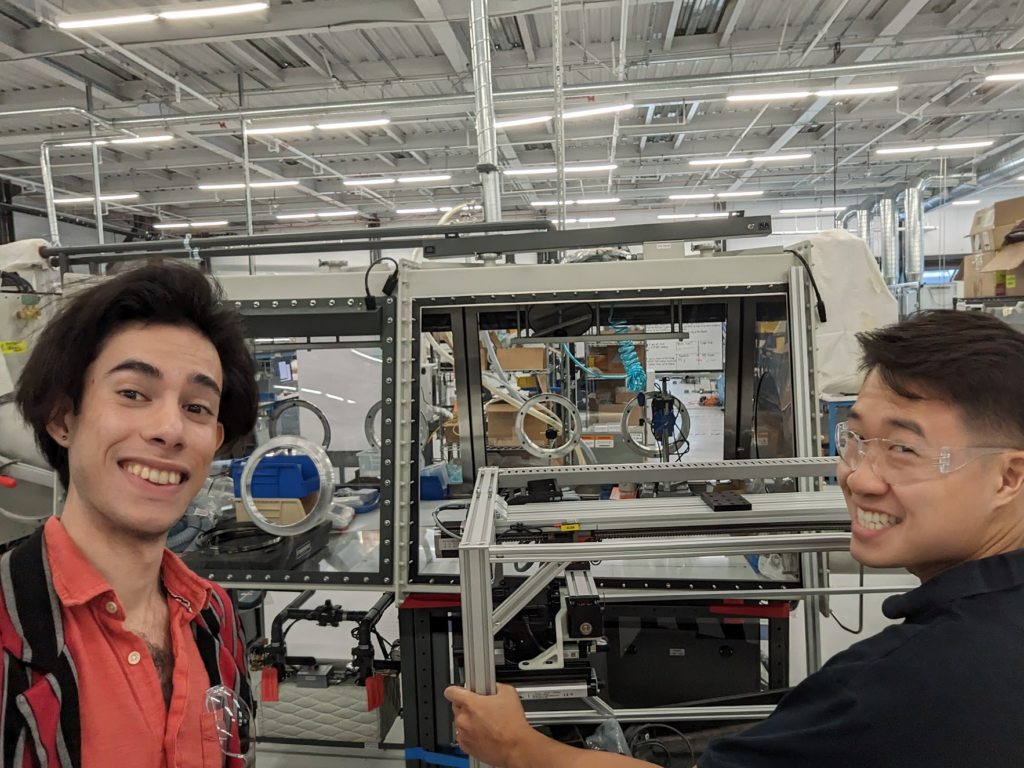

Equipment Engineering Intern: May 2023 – May 2024

Unfortunately I can’t share the sort of details I have for my other work, as my work at tesla is protected under my NDA and the nature of some of the work in lithium ion cell research and development is pretty confidential!

However, I can share about what sort of projects I worked on and what my experience was like:

For my second engineering internship, I signed onto the Tesla Cell Development Lab Equipment Engineering team for an 8 month internship in Palo Alto, CA. I didn’t know quite what to expect, but I soon found that the work was dynamic, that I had great ownership over my projects, and that this was an excellent opportunity to challenge not only my design abilities, but also my project management ones. I was offered an extension for 4 months and took it. This allowed me to take on several larger scope machine design projects towards the end of my internship.

The environment at Tesla is fast-paced. Often times, work needs to get done quickly, and if it’s not done quickly, it’s not very useful. I had to confront a strong desire to seek perfection in my designs, and reconcile this with the need for functionality in the near-term. I won’t pretend that I have mastered this ability – it is very difficult and I am still working on it. But this experience at Tesla allowed me, most of all, the opportunity to practice and improve my discernment of when and where it’s worth putting my effort.

On our small team of five equipment engineers, we mostly take individual ownership over projects to enable new research and improved yield and throughput in our cell manufacturing. These projects can be as simple as fixture redesigns and trays to enable better organization and efficiency, and as complex as new custom machine designs for novel process development. I was fortunate to work independently on many projects on both ends of this spectrum over my 12 months.

Here’s some distilled info on my role and work:

- One of five equipment engineers enabling the research and development work of Tesla’s Cell Development Lab with custom designed in-house equipment as well as modified vendor equipment for electrode and cell manufacturing, QC, and testing

- Developed novel cell dissection analysis tool and software from the ground up, enabling vast improvement to dissection data quality and consistency

- Led external vendors through design scaling and commissioning of above dissection analysis tooling to bring my work to five additional Tesla teams throughout the US, creating new benchmark for cell dissection analysis company-wide

- Continually led projects from conceptual design through to in-house and external manufacture, assembly, documentation, training, release to lab technicians, and support

- Spearheaded novel process improvements improving cell yield by up to 40%

- Engaged technicians in ergonomic design projects to increase efficiency, comfort, and process repeatability across our lab