One of the first projects I was given at GluxKind was to redesign the stroller’s central joint to be made from 3d printed plastic as opposed to CNC-machined aluminum parts. Many of the features that made this design possible relied on circlips, spring washers, pins, and precise machining. My goal was to retain the exact same mechanical function, including the elegant lock mechanism, all within the same external package as the previous joint. This was not intended to be installed on a stroller, but rather shared with a partner company who was helping with the design and exploring options for costing down the joint.

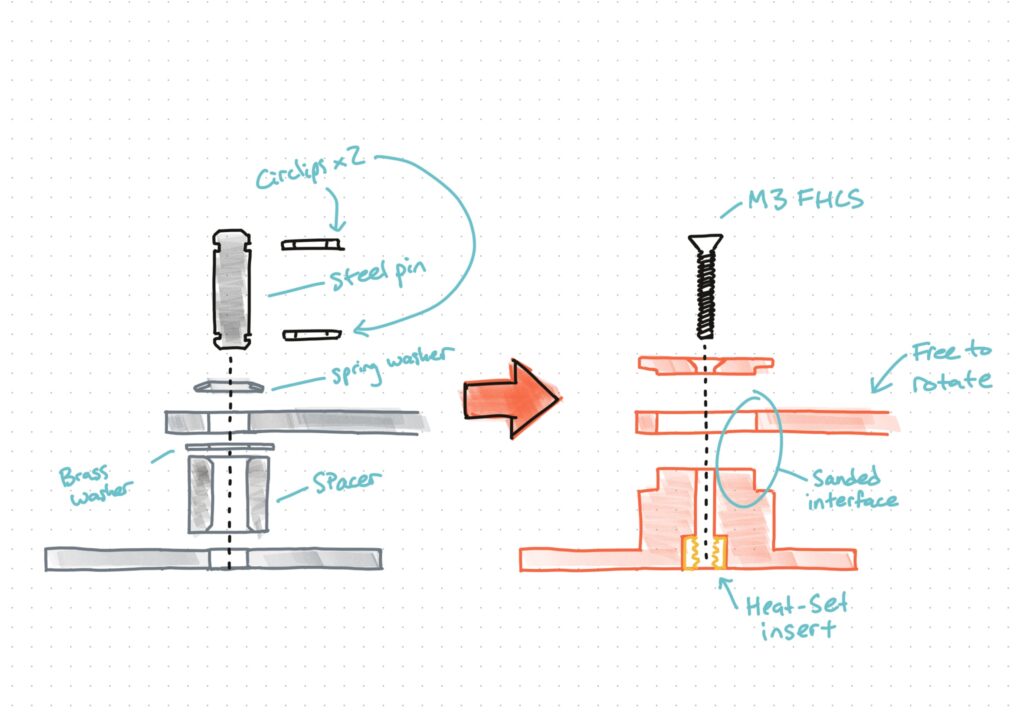

I first set off finding ways I could replace spacer, pins, and circlips. Many of the aluminum parts were pinned together, and I knew that some strength would still be required in these joints. I eliminated spacers and acme up with a stacking system for 3D printed PLA parts that have a central bolt for strength, like so:

The benefits here are that we minimize the number of parts required, retain some strength from the central bolt, and also introduce a bit more compliance which is beneficial in avoiding the joint seizing how many parts need to fit together to form the joint. I got to work redesigning the entire joint CAD to adopt this new fastening method, and then started printing these components on my self-built 3d printer which I brought into work as we were on a tight schedule!

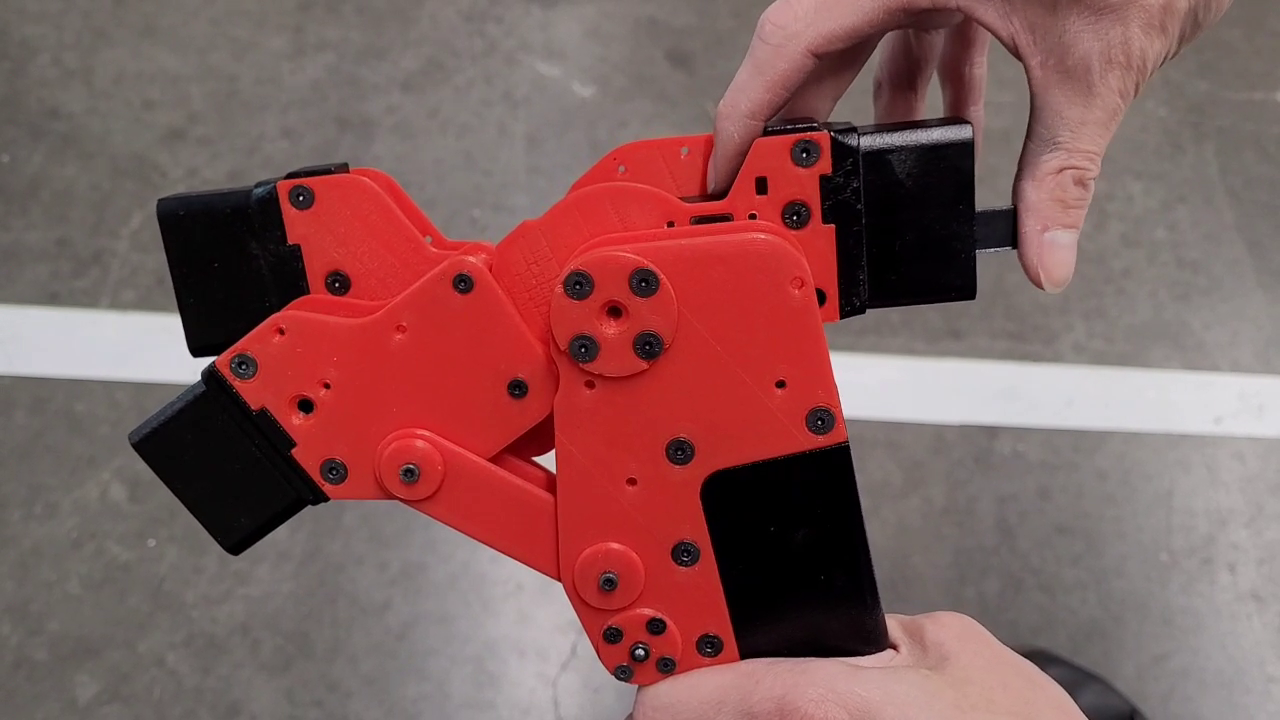

After fine-tuning the rotating interface tolerances and extrusion characteristics of the printer, I was able to print all the parts with minimal sanding required for smoothness. After heat-setting all the inserts, I began assembling the joint, and I’m proud to report that it worked great and even the push-lock mechanism worked! here’s a video showing the action:

Design Outcomes

+

Zero change to external dimensions, geometry, or mounting features

~50%

reduction in parts

+

Joint lock mechanism fully functional

Skills and Learning

•••◦◦

Mechanical Design

••••◦

DFMA

••••◦

3D print tolerancing and tuning for secure rotating joints

Leave a Reply