Rounding out our shop, we have our 3D print shop, Electrical Lab, and small waterjet cutter and CO2 laser.

I’d like to be clear that I’ve not been primarily responsible for any of these tools or areas, but I have provided support and trainings to students in all areas throughout the years. Students like Viktor Moreno, Marvin Shi, Sarah Jang, Rocky Cao, Zach Huser, Hayden Sass, Ivy Reisner, Jordan Myers, and most recently Katie Law (new head shop supervisor!) and Charles Polloway have been instrumental in maintaining these spaces and training folks up.

3D Print Shop

In the Print Shop, we are able to process students’ submitted STL files and prepare them for printing on our FDM or SLA printers, print, and then drop off to students in our clubroom. This is a free service, and students use it mainly for work on their IGEN capstone design courses as well as personal projects.

I spent time helping out in the print shop early on in my degree, preparing many prints on our Form 2 and Anycubic Mono SLA printers as well as our Ender 3 and later fleet of Prusa i3 Mk3 FDM printers. This was my first experience using SLA and PreForm and the experience would come in handy for my later work at Tesla!

Electrical Lab

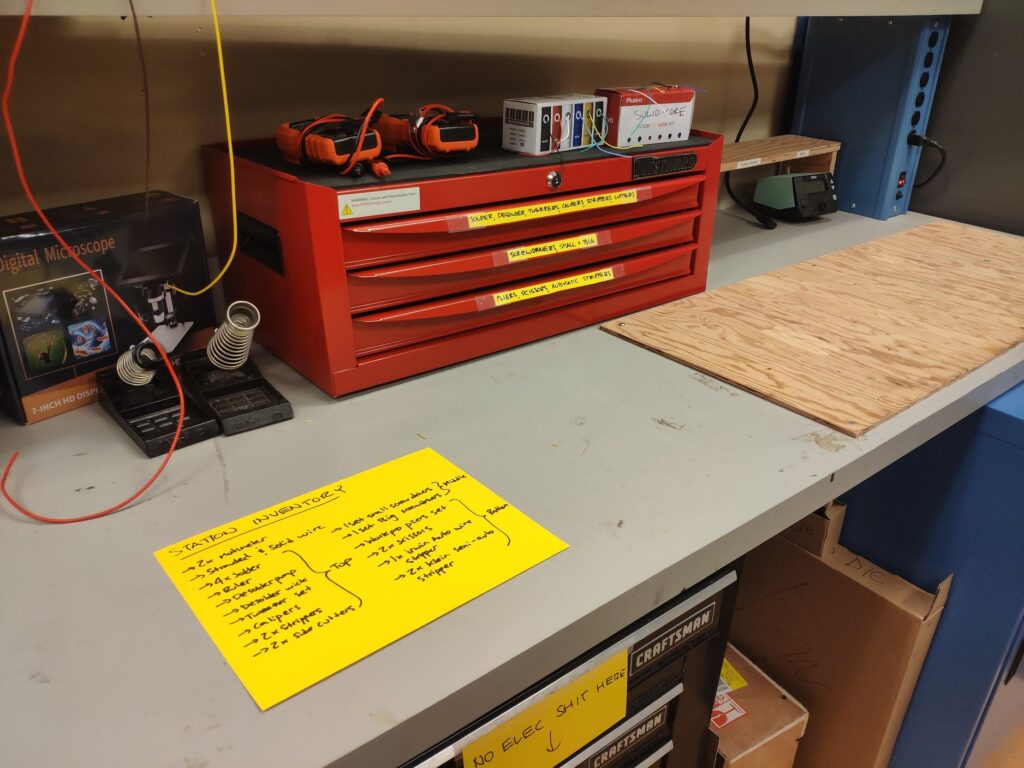

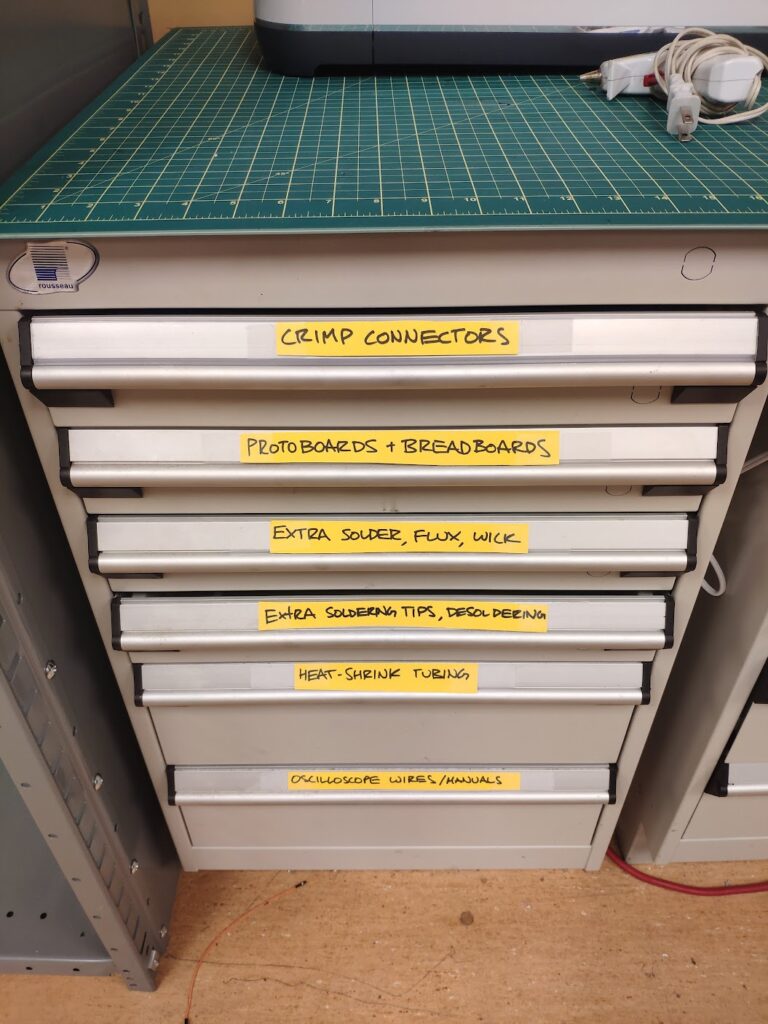

Our electrical lab has 4 stations with basic soldering and wiring supplies, some basic components, oscilloscopes and variable power supplies. In this lab I’ve done some organization work – Everything seen in yellow is one very late night’s work by me after being very frustrated with disorganization. In the time since the space has been managed by others and they have done good work to keep the spaces useful for students.

I also ran several training sessions in 2022 on basic electronics work – soldering and desoldering wires, crimping, using protoboards, and building a small metal detector project from a kit with small groups of students.

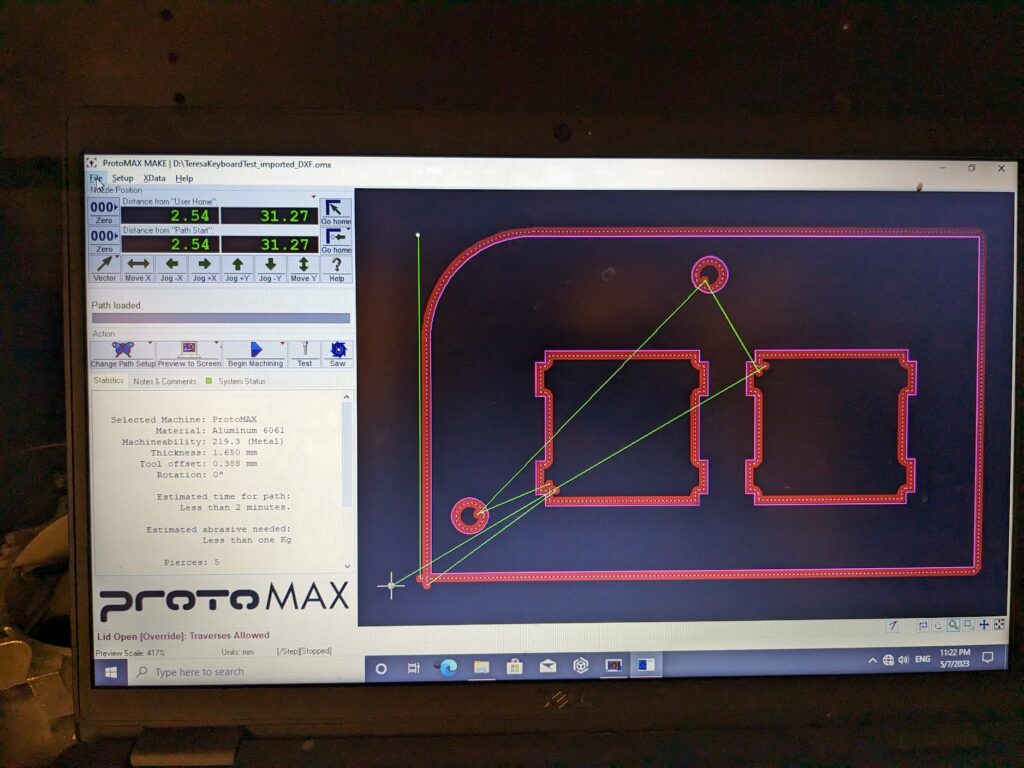

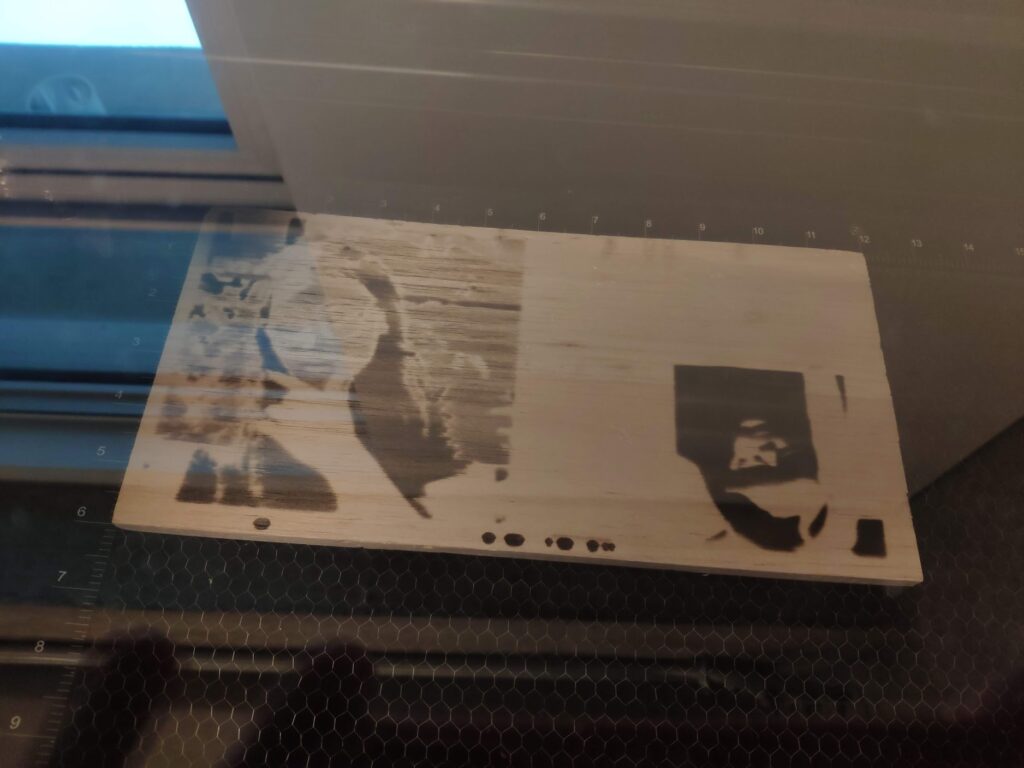

Waterjet and Laser Cutter

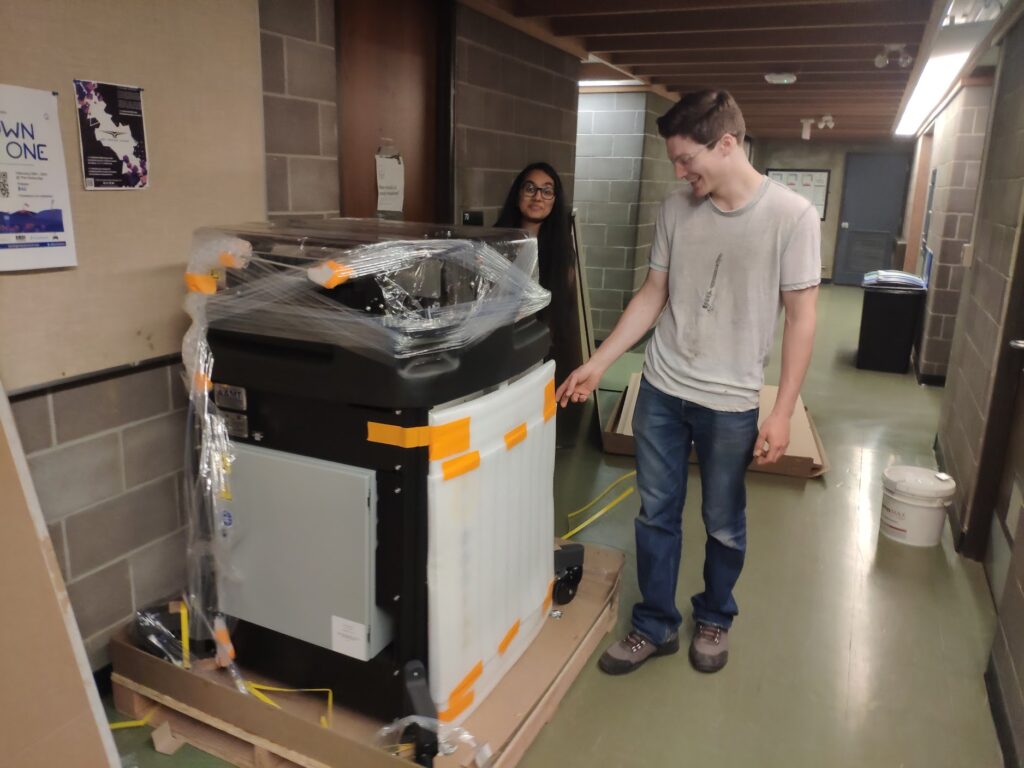

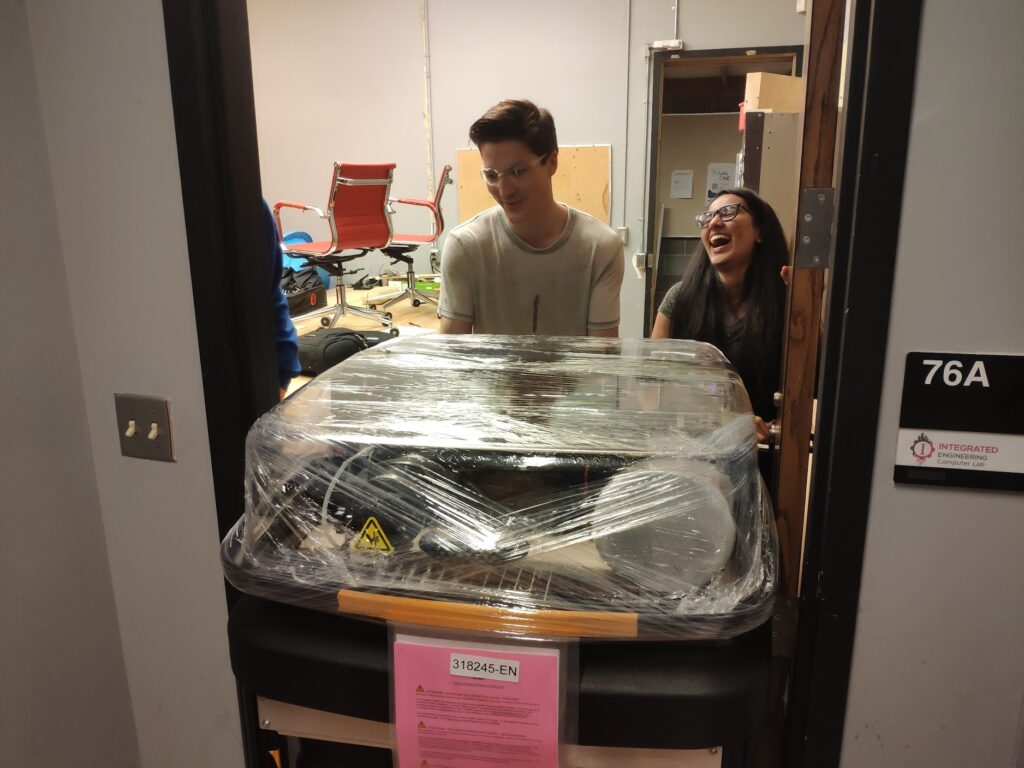

Over 2022 and 2023 we have gained our OMAX ProtoMax 12″x12″ waterjet and our 24″x36″ CO2 laser cutter, both of which I have helped set up and ran some trainings for early on. The waterjet cutter, while it can be a pain to set up and the software is most certainly a pain to use, has been amazingly useful for many IGEN and design team projects. The laser unfortunately has been housed in another building and gets less frequent use, but hopefully with upcoming shop reorganization we can move it into our area!

Mill and Lathes

Finally, we have our manual knee mill and lathes, both of which I have also run trainings on and helped out peers with projects for their IGEN Capstone designs and personal projects. These are old machines but have been very useful for us, and Zach’s work to install a DRO on the knee mill was great! Below you can see a video tour of our whole shop area, including the lathe and mill area near the end:

Project Outcomes

Expands

our students’ access to and confidence with machining processes

Builds

our shop supervisors’ talents as educators and improves our student body’s collective knowledge and ability as manufacturers

Unlocks

Potential for more ambitious student projects within the IGEN capstone design community

Skills and Learning

•••••

Leading hands-on technical training of 5-10 person groups

•••••

Working one-on-one with students to help them with their projects

•••••

maintaining and ensuring safety across a multitude of shop spaces

Leave a Reply