In the summer before I began my Integrated Engineering studies, I spent a lot of time hanging out with my friends Zach Huser and Mark Greenwood, the IGEN shop managers at the time. We worked to improve and organize the shop for the upcoming year, but despite several trips to home depot and princess auto, the shop was still missing some critical infrastructure – a CNC mill.

This led to the purchase of a Tormach PCNC 1100 CNC mill. Over the following years, this machine would ultimately be replaced, but this was the genesis of a long story of caring for CNC mills within the IGEN shop community.

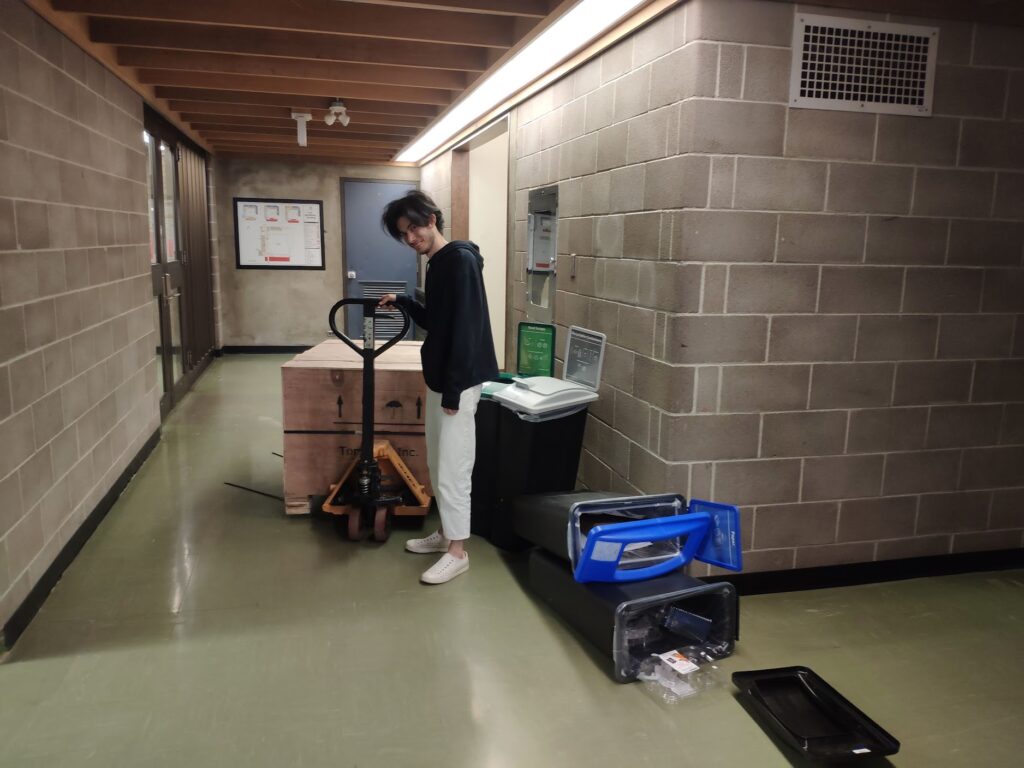

Let’s start with the PCNC 1100, which we went to pick up in Delta, BC with a semi truck, brought back to campus, and installed in the shop:

It only took a couple door removals to get the machine into the shop! We began setup, cleaning, waterproofing the enclosure, and organizing the boxes of endmills and extras that had come with the machine off the seller on Craigslist. We built some dooAfter stocking up at the metal recyclers, we started testing the mill!

Zach noticed that the spindle would make a pretty grating screeching sound and you could feel rough, inconsistent rotation when rotating it by hand. So the first upgrade we made to the machine was to install a new spindle, which we ordered up and I installed:

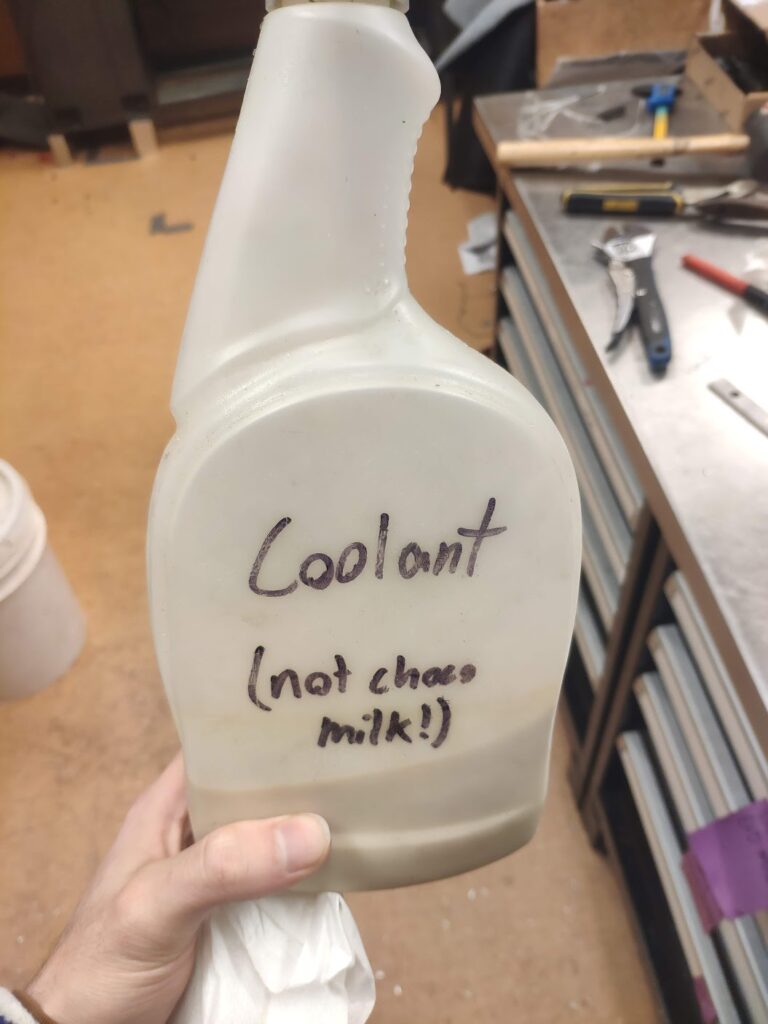

Next, we needed to address a major problem with the mill’s coolant system. It’s inadequate. The small coolant reservoir when coupled with the large flow restriction for coolant trickling through a very restrictive and chip-clogged filter meant that the coolant pump often had nothing to pump. This bottle was serving as our coolant pump for a few months:

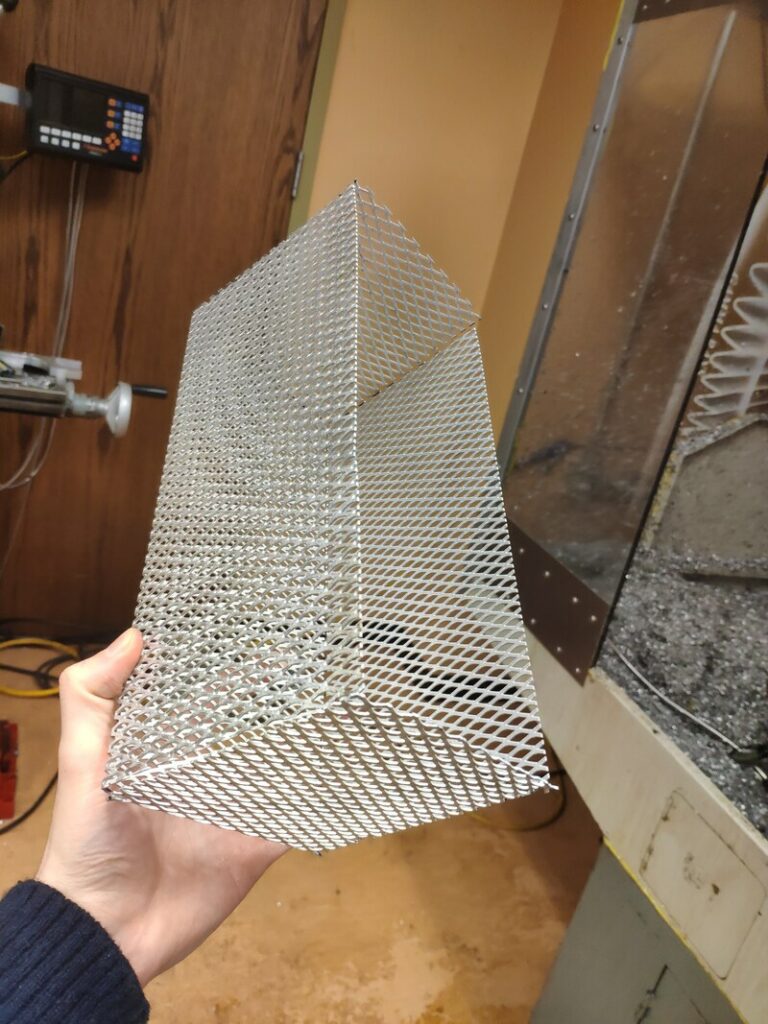

We went to get a stronger pump from princess auto, decreased the flow restriction out of the filter stage by welding on a larger outlet for our tubing, used a MUCH bigger rubberneck container to increase coolant volume, and fashioned a second, coarser, filter stage:

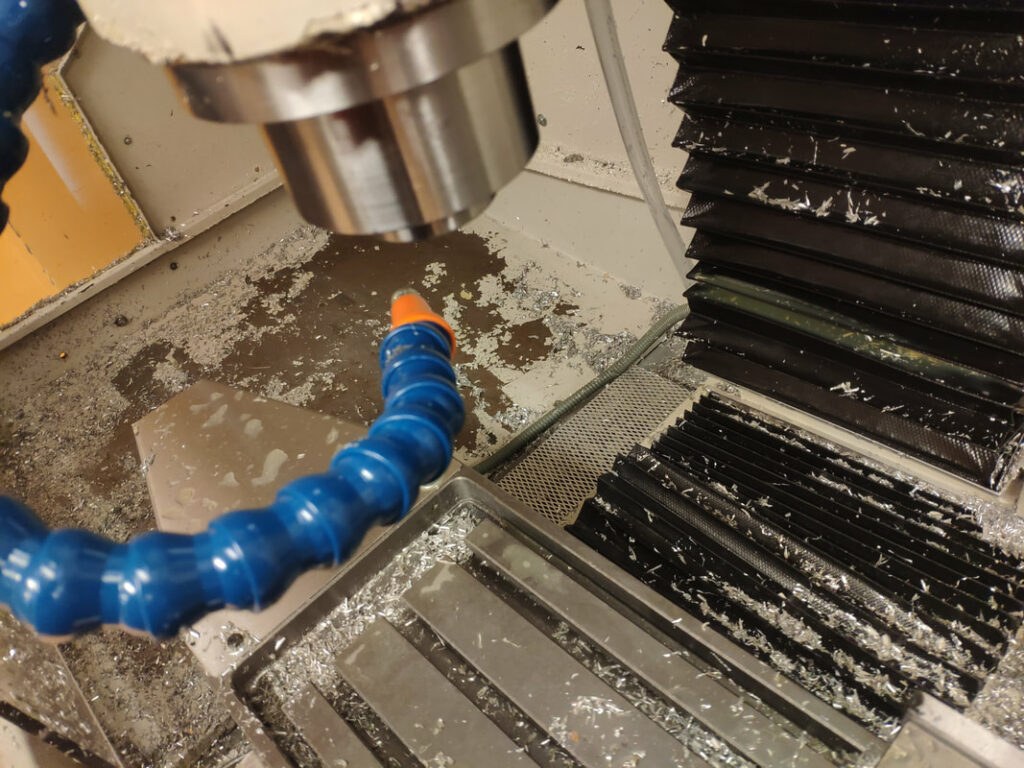

Finishing up some plumbing, we attached some larger loc-line to test the coolant system out:

This machine served our students for a year, and it was an excellent learning tool. It’s simple and quite universal post processor (mach3mill) compatibility and the cheap price we got it for meant it was perfect to make mistakes on and gain valuable experience. After many successful projects completed, this machine was ultimately donated to the UBC Rocket design team by Zach, and we prepared for a new arrival:

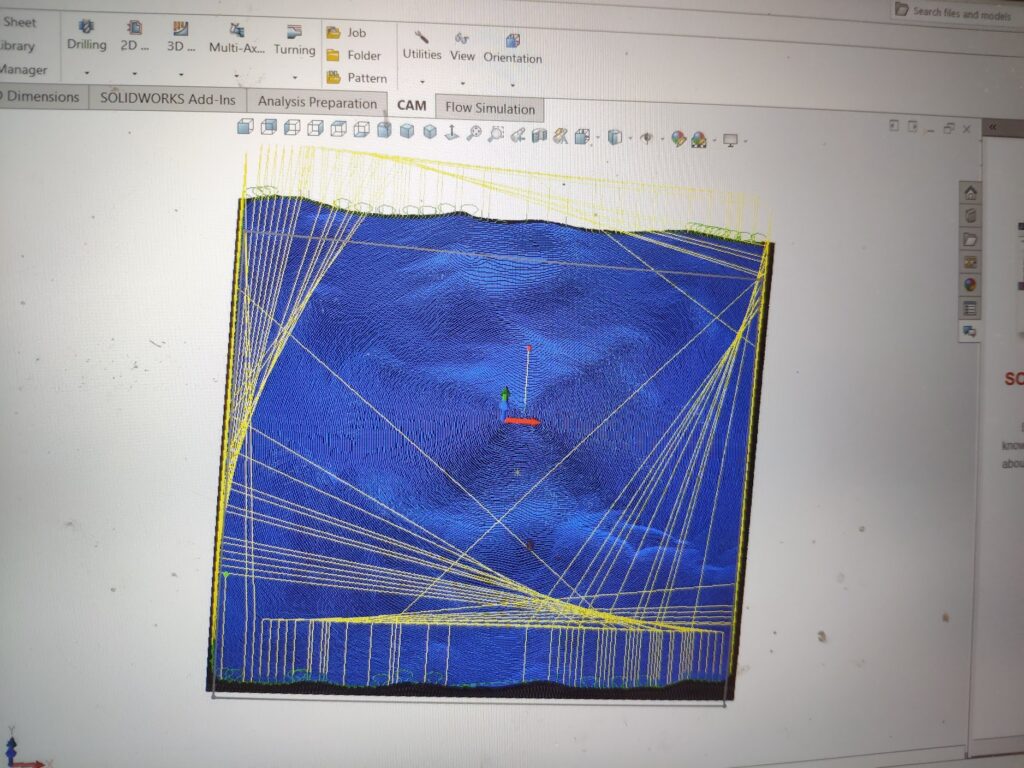

After a few days of exciting work, our brand new Tormach 1100MX was up and running. This purchase was made directly by IGEN, and our work with the PCNC 1100 that Zach bought with his own funds proved our capacity to not only use this kind of equipment, but maintain, train, and supervise the completion of amazing student projects using it. The 1100MX has been amazing for our student community as well as for the UBC engineering design team community, and we have been running extensive trainings for this machine within both communities.

Upgrades over the months of use include setting up and installing the Automatic Tool Changer unit as well as starting to play with the 4th axis attachment, and further organization of more and more endmills, tools, collets, etc.

We remain the only engineering faculty with student-run, student-trained, and full, free access to a high-quality CNC mill, and this is thanks to both the support of our faculty and the hard work of the shop management team.

Project Outcomes

Expands

our students’ access not only to CNC machining, but to education and hands-on training on how to use a CNC mill themselves with our help

Unlocks

Potential for much more ambitious student projects within the IGEN capstone design community as well as the UBC engineering design team community as a whole

Skills and Learning

•••••

Industrial machine assembly, calibration, maintenance

Leave a Reply